-

Inspector Pumphead’s Classroom: Training with Alderon Industries

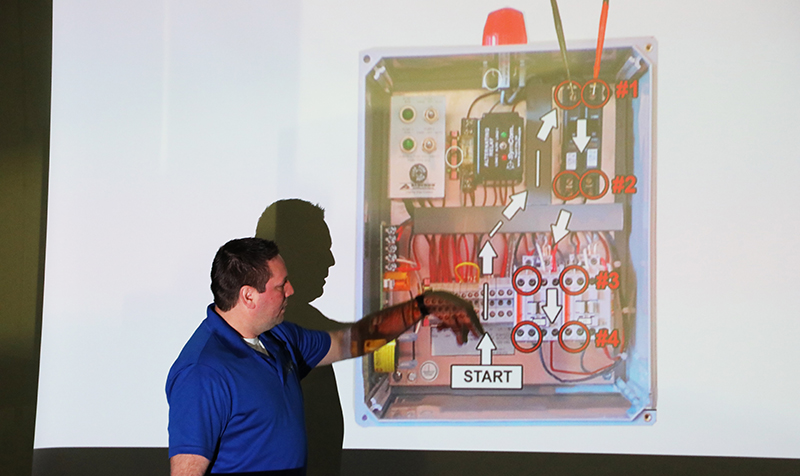

January 11, 2018Pump Products staff members recently attended a technical training session with the national sales director of Alderon Industries, one of the company's newest manufacturing partners. Alderon specializes in making high quality control panels, floats and alarms.This session was part of a continuing effort by the team to better educate themselves on the products we carry and in turn help customers choose the best products for each one's need and budget. Ben Moy of Alderon conducted the illuminating training session using a PowerPoint presentation and several display control panels as physical examples. He started by laying out the history of Alderon Industries. Initially founded by one of the lead engineers of SJE Rhombus (then SJE Electric) control panels, Alderon's purpose was to create a new generation of control panels. One of the original Alderon designs introduced a rubber gasket in the lining of the panel door to keep out rain. The inspiration for the company's name indeed comes from the planet from "Star Wars"; the two cofounders were watching the classic sci-fi film while brainstorming potential names (though as any geek can tell you, the planet is spelled Alderaan in the movie). Moy walked the Pump Products crew through the basics of the popular "Check It" series of control panels. Perhaps the defining feature of this panel series is the ease of connecting the pump and floats to the right terminals due to careful labeling. Moy noted that with other panels, confusion can often reign. "In a lot of states, the only person who can set up a panel is a certified electrician. So a municipality will order the panel and have it sit for days, weeks even," he said. "By the time the electrician comes, they've thrown away the instructions and no one knows what goes where." All Check-It panels carry labels on the cords for the pump itself, the "off" float, the lead float and the alarm float (if applicable) to connect to the correct terminals. Moy also demonstrated how the circuit board is hardwired into the terminal and into the HOA (Hands Off Automatic) switch. Additional features in the panel include a pump run indicator, float switch indicators and alarm power indicators. Moy also demonstrated how a jump wire within the panel gives an alarm notification for manual reset. The jump wire can also be removed for automatic reset. The Pump Products team was also given a sneak preview of some exciting new Alderon products that could be due for release in March. Be sure to check back in this space for more information on them. "This was a really great technical training session in the sense that we were given a good demonstration of how the products look and how they operate," according to Pump Products application engineer Lee. "Seeing the detail in how the panel works will definitely help us in giving advice to customers." Pump Products is continuing to add more sessions to better understand manufacturer products. Be sure to take a look at the Alderon controls that we carry and call if you have any questions. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Classroom: Training with See Water, Inc.

November 20, 2017As part of an ongoing effort to provide the best possible service for all product lines, Pump Products employees attended a training session with a representative from See Water Inc. See Water, located in Riverside, CA, is one of Pump Products' newest manufacturing partners and is renowned in the industry for its line of innovative water products and controls. Pump Products currently carries a plethora of quality wastewater pump control accessories from See Water, including water level alarms, control panels and junction boxes. Eric Wallace, Vice President of Operations at See Water, gave a presentation lecture in which he dove into the history of the company, its products, and practices for ensuring across the board customer satisfaction. "We're a customer-driven company and we pride ourselves on great customer service," he said. "Our focus is always on the end user." Wallace said that this focus is best exemplified by the simplicity and straightforwardness of See Water installations. He described his ideal customer interaction as, one in which the customer is able to install the product so easily that he feels compelled to call the company to make sure the process really is that simple. That's why many See Water products are "plug and play" an approach that emphasizes the end user in the consumer interaction chain. This produces return customers, and according to Wallace, there's nothing See Water likes more than return customers. It is a philosophy that Pump Products shares as well. Another, incredible fact is that, all See Water products are constructed at the company facility in Riverside, CA. Having everything manufactured in the U.S., is an important mark of quality. All products are also UL-listed and CSA certified for the U.S. and Canada. Such customer care also extends to the warranty process. Most See Water products (except custom builds) include a 3-year warranty. Wallace estimates that "90%" of warranty issues are able to be resolved through calling the company directly and troubleshooting. This allows the user or contractor to solve the problem onsite. In cases where that doesn't work out, customers can send the product back to See Water for thorough examination. "We're just interested in the customer being happy," he said. Testing is also an important aspect of the process. Each product that leaves the warehouse is factory tested before it is packaged. Wallace emphasized that the testing is not a la carte but holistic. "We don't have a station with a bunch of floats and then hook up a panel to test it," he said. "We test each control panel with the specific float that will be in the package before it gets sent out. That way the customer is sure to get everything that works." For lead times, prebuilt products can usually be sent to Pump Products within a matter of days. Custom panels can take up to four weeks but See Water tries to push those panels through sooner if possible, particularly for repeat customers. See Water also emphasizes the commonality of various parts and components across various types of panels. This allows the engineers to rig up all sorts of custom panels, with special custom features, tailored to make the user's life much easier. Some of these features include but are not limited to: touchscreen interfaces, variable frequency drives, programmable logic controllers, multiple alarms (that can be run back to a main alarm) and solar alarms. The thoroughness of the engineering process allows for a lot of same-day and next day quotes on custom panels. Making sure exactly what each customer needs, also reduces the risk of returns and call-backs. "It was a really interesting and informative lecture," Pump Products application engineer Nick said. "It's always good to get insight into how other companies interact with customers and think about how we can apply those practices here [at Pump Products]." The training session with See Water is part of a continual effort by the Pump Products staff to familiarize themselves with manufacturer products, to deliver the best possible service and product information to our customers. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Classroom: Training with A.Y. McDonald

September 14, 2017Pump Products recently held a training seminar and Q&A session with Michael, the Northeast territory manager representing A.Y. McDonald Mfg. Co. This training session was just one of a number of such sessions designed to familiarize Pump Products application engineers and marketing staff with a manufacturer’s products, processes and customer service capabilities. Pump Products employees will in turn be able to better communicate about those products to customers. The talk centered specifically on A.Y. McDonald’s versatile and well-built submersible well pump line. The strength of A.Y. McDonald well pumps lies in their quality construction; all pump ends are made and manufactured in the United States. The target market for these well pumps is the discerning consumer who is willing to pay for quality manufacturing. While A.Y. McDonald has experimented with imported pump ends in the past, according to Michael, the company has rededicated itself to domestic manufacturing centered in its factory in Dubuque, IA. Keeping design and manufacture in-house allows the company to have “wonderful customer service,” according to Michael. “It’s a very tight knit and family-oriented group,” he said. The focus on customer service is particularly important for A.Y. McDonald because it is a “boutique” manufacturer. That focus extends to shipment (A.Y. McDonald can drop ship directly from the factory) and to the warranty process. Most pumps carry a one year warranty, but extended warranties up to three and five years are also available. Michael estimated that he fields about one warranty request per month. The group also talked about A.Y. McDonald’s vaunted SludgeMaster pump. Commonly used to get radon out of water cisterns, the SludgeMaster is powered by an air compressor and can evacuate mud, gunk, leaves, twigs and other waste from a system. While it can’t run on pure solids - the pumping medium should be about 70% liquid - the SludgeMaster is still a heavy duty pump. It has been described as an “animal” or “beast.” All in all, it was an enlightening and invigorating training session that strengthened the partnership between Pump Products and A.Y McDonald and has better equipped Pump Products to better serve the customer needs. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800.

-

Inspector Pumphead’s Classroom: Training with Franklin Electric

June 21, 2017Representatives from Franklin Electric swung by the Pump Products office on Tuesday, June 20 for a training session with the company application engineers, marketing team and administrative staff. The session was part of an ongoing effort to ensure that Pump Products employees have a thorough understanding of the pumps the company sells and to ensure that all employees can communicate those intricacies to customers. Proper pump sizing is the most critical function for any pump distributor. A customer should be able to rest easy knowing that he or she will receive the right pump for their specific application. The session focused specifically on the features, uses and benefits of Red Lion well pumps. Franklin recently acquired Red Lion and is positioning its wide range of pumps as a dominant force in the domestic pump market. Tim, a Franklin Electric sales manager specializing in HVAC and outdoor pumps, gave a thorough and detailed presentation on groundwater and the various types of well pumps, including shallow well, deep well and convertible. He also laid out the construction type and features of each type of pump. For instance, many models will include pipe packages and/or control panels. “The [Red Lion] pump packages are very convenient for homeowners because a lot of the necessary components come included with no additional purchase,” according to Tim. “It’s essentially ‘turn key’ operation.” Pump Products employees were free to ask questions, make suggestions and discuss the various options for each pump. It was a fruitful dialogue that will hopefully help all members of the Pump Products team help customers choose the best possible pump. The team was also able to broach the idea of a streamlined warranty process which could potentially save all parties time and money. “We’ve done a few of these training sessions and I think that this one might have been the most helpful,” according to applications engineer Nick. “It wasn’t just about how to push product but to actually think about the best way to inform customers.” “It was really interesting to learn about the different types of well pumps,” says videographer Mike. For more information on Red Lion well pumps or any other products, be sure to call and speak to one of our application engineers today at 1-800-429-0800. (Adverts for Little Giant and Red Lion)