-

Advantage of Goulds Pumps: Types & Benefits

January 13, 2020Anyone who knows much about pumps knows that Goulds pumps are among the best. The Goulds brand is globally recognized and respected, available in over 150 countries worldwide, and the quality speaks for itself. Whether buying in stores or buy Goulds pumps online, people frequently search the web for a “Goulds pump dealer near me” precisely because they know they’re getting a quality pump! If you’re in the market for a new pump, read on for more info about the types of pumps Goulds offers, as well the benefits of buying from this well-known, high-quality brand. The Many Types of Goulds Pumps Goulds is known for quality, but their vast portfolio of products is also truly impressive. Here are some of the types of Goulds pumps you can buy online and at your local dealer: Booster Pumps These quiet pumps are built to use in a wide variety of applications. Nearly vibration-free, Goulds booster pumps come in several possible options: •The Goulds Aquavar ABII Series is a complete booster system all in one. This kit comes with the pump, pressure tank, plus a variable speed controller and transducer. •Goulds GB Series pumps are built for managing agricultural and residential washdown. •The Goulds HB Series are great for high-pressure situations like condo high-rises or office buildings. •The LB Series are stainless-steel encased pumps for use in systems requiring a flow rate of up to 18 gallons per minute. Centrifugal Pumps Goulds offers several types of both horizontal and vertical centrifugal pumps with head capacities ranging from low to high. All Goulds centrifugal pumps are constructed with durable materials made to withstand the hardcore demands of agricultural, residential, and/or commercial use. Dewatering Pumps These Goulds pumps are light, portable, and submersible, made to be used wherever there’s a need to pump standing water. Effluent and Septic Pumps Designed with a variety of grey- and wastewater applications in mind, Goulds effluent pumps are submersible and made of high-quality materials. They are available in manual and automatic models. Sewage Pumps Made specifically to handle sewage and wastewater, Goulds sewage pumps have single-phase motors with a thermal-overload protection feature to ensure your pump will last through the toughest jobs. Sump Pumps With electric, battery-powered, and water-powered options, Goulds sump pumps are built to prevent your basement from flooding by draining any standing water in your sump pit. They’re also made to be corrosion resistant and easy to service. Well Pumps When your home is not connected to a municipal water supply, the odds are that you have a well that requires a high-quality pump to meet your family’s water needs. Goulds well pumps will exceed your expectations with convertible, submersible, shallow, and deep well options. These pumps also work well in small-scale irrigation and livestock water systems. Other Types of Goulds Pumps Goulds also offers elevator, explosion-proof, high-temperature, trash, and grinder pumps, as well as sink pump systems. The Goulds Standard: Benefits of Buying a Goulds Pump Goulds pumps have been on the market for several decades, so you can be certain that their quality has stood the test of time. You can also rest assured that they’ve kept up with changing pump technology. They’re one of the best brands in the industry for a good reason, and when you buy a Goulds pump, you know you’re getting a high-quality resolution for your pumping needs. Whether you’re dealing with a wet basement in need of a sump or an old well with an antique pumping system or you’re a builder with a large-scale pumping project, Goulds has you covered with an efficient and sustainable solution. Their pumps go through rigorous testing and meet strict temperature, corrosion, abrasion, and pressure standards. And Goulds is the only manufacturer of process pumps in the market that offers digital monitoring as a standard feature! PumpProducts.com: Your Goulds Pump Dealer If you’re in the market for a pump, check out our full-service website or contact our Goulds customer support counter at 1-800-429-0800. We specialize in Goulds pumps, and we’re one of the largest online dealers for this well-known and highly respected global pump brand. We just so happen to offer them at the guaranteed lowest price, too! Whether you’re a direct consumer, small to mid-sized contractor, or a large commercial, industrial, or municipal entity, when you’re looking to buy Goulds pumps online, PumpProducts.com is here for you. Also, we offer Goulds pump accessories, alarms and controls, and repair parts as well. We’ve got everything you wish to get the work done right!

-

Goulds Well Pumps: 4 Different Types & Their Uses

October 9, 2019Anyone who knows much about pumps knows that Goulds water pumps, including Goulds convertible pumps and Goulds submersible pumps, are among the best on the planet. The Goulds brand is globally recognized and respected, available in over 150 countries worldwide, and the quality speaks for itself. If you’re in the market for a new well pump, read on for more info about the four types of well pumps Goulds offers, as well their uses and the benefits of buying from this well-known, high-quality brand. The 4 Types of Goulds Well Pumps When your home is not connected to a municipal water supply or if you have small-scale irrigation and livestock water systems on your farm, you probably have a well that requires a high-quality pump to meet your family’s and/or farm’s water needs. Goulds water pumps have you covered. Goulds well pumps come in four different types to meet your water pumping requirements. They offer submersible, shallow, deep, and convertible well pumps. Here’s a bit more about each type and its uses. Submersible Well Pumps Typically used for wells that are greater than 110 feet deep (except in certain elevations, where they can be used in shallower wells), submersible pumps are exactly what the name implies. They are pumps that sit inside the well, submersed underwater, and they’re unique in that they push the water up and out of the well through a pipe. Goulds submersible pumps feature a Centripro motor and corrosion resistant pump body that is made to last. Shallow Well Pumps When you have a shallow well, where the water table sits at a depth less than 25 feet, you’ll need a Goulds shallow well pump. These pumps are specifically designed with a shallow well adapter integrated to allow you to pull water from shallow depths to wherever you need it—without the need to buy a separate adapter part. Deep Well Pumps Goulds deep well pumps are just what they sound like. These pumps are made to use in applications where the water needs to be pulled from depths greater than 25 feet. Convertible Well Pumps With the proper fittings, Goulds convertible pumps are versatile enough to be configured to work for either shallow or deep wells. The Goulds Standard: Benefits of Buying a Goulds Pump Goulds pumps have been on the market for several decades, so you can be certain that their quality has stood the test of time. You can also rest assured that they’ve kept up with changing pump technology. They’re one of the best brands in the industry for a good reason, and when you buy a Goulds water pump, you know you’re getting a high-quality resolution for your pumping needs. Whether you’re dealing with a wet basement or an old well with an antique pumping system, or you’re a builder working on a large-scale pumping project, Goulds has an efficient and sustainable solution to fit your needs. Their pumps go through rigorous testing and meet strict temperature, corrosion, abrasion, and pressure standards. And Goulds is the only manufacturer of process pumps in the market that offers digital monitoring as a standard feature! PumpProducts.com: Your Goulds Well Pump Dealer If you’re in the market for a new Goulds well pump, check out our full-service website or contact our Goulds customer support counter at 1-800-429-0800. We specialize in Goulds water pumps, and we’re one of the largest online dealers for this well-known and highly respected global pump brand. We just so happen to offer them at the guaranteed lowest price, too! Whether you’re a direct consumer, small to mid-sized contractor, or a large commercial, industrial, or municipal entity, when you’re looking to buy submersible pumps online, PumpProducts.com is here for you. Plus, we offer Goulds pump accessories, alarms and controls, and repair parts as well. We’ve everything that you wish to get the work done right!

-

Myers S Series Submersible Well Pumps Buyers Guide & Review

May 29, 2019The Myers S Series 4” submersible well pumps have been a successful entry in the Myers well pump line for many years and have a history of tremendous reliability. The all stainless steel construction is ideal for extreme water conditions and easily resists harmful corrosion. The S Series subs are also available with high-performance Pentek motors for the very best in efficiency and trouble-free operation. Features 300 series stainless steel straps 300 series stainless steel discharge Rubber discharge bearing 300 series stainless steel impellers stand tough against sand and grit 300 series stainless steel diffusers 300 series stainless steel suction caps 300 series stainless steel shaft and coupling 300 series stainless steel intake 300 series stainless steel intake screen 300 series stainless steel cable guard 300 series stainless steel check valve 300 series stainless steel fasteners Precision crafted for smoother, quieter operation Features application-matched Pentek motors for just the right mix of performance and efficiency. Built-in hook assembly keeps pump safe from slip Applications Water system: Residential Industrial Commercial Multiple housing Farm clean water use MYERS S SERIES SUBMERSIBLE WELL PUMPS Model Comparison Chart Model Discharge (NPT) HP Voltage Stages GPM Best Efficiency Flow Shut Off Head 3S52-10-P4-01 1-1/4" 1/2 230 9 10 230' 3S51-10-P4-01 1-1/4" 1/2 115 9 10 230' 3S52-16-P4-01 1-1/4" 1/2 230 5 16 150' 3S51-16-P4-01 1-1/4" 1/2 115 5 16 150' 2S51-10-P4-01 1-1/4" 1/2 115 9 10 230' 3S52-25-P4-01 1-1/2" 1/2 230 3 25 100' 2S52-16-P4-01 1-1/4" 1/2 230 5 16 150' 2S51-16-P4-01 1-1/4" 1/2 115 5 16 150' 2S52-25-P4-01 1-1/2" 1/2 230 3 25 100' 3S52-5-P4-01 1-1/4" 1/2 230 13 5 350' 3S72-25-P4-01 1-1/2" 3/4 230 5 25 150' 3S72-10-P4-01 1-1/4" 3/4 230 12 10 320' 2S52-5-P4-01 1-1/4" 1/2 230 13 5 350' 2S72-25-P4-01 1-1/2" 3/4 230 5 25 150' 3S102-16-P4-01 1-1/4" 1 230 10 16 300' 3S72-16-P4-01 1-1/4" 3/4 230 8 16 240' 2S72-16-P4-01 1-1/4" 3/4 230 8 16 240' 2S72-10-P4-01 1-1/4" 3/4 230 12 10 320' 3S102-25-P4-01 1-1/2" 1 230 7 25 210' 3S102-10-P4-01 1-1/4" 1 230 15 10 400' 2S102-16-P4-01 1-1/4" 1 230 10 16 300' 3S72-5-P4-01 1-1/4" 3/4 230 18 5 500' 2S102-25-P4-01 1-1/2" 1 230 7 25 210' 3S152-16-P4-01 1-1/4" 1-1/2 230 14 16 420' 2S102-10-P4-01 1-1/4" 1 230 15 10 400' 2S72-5-P4-01 1-1/4" 3/4 230 18 5 500' 3S152-25-P4-01 1-1/2" 1-1/2 230 9 25 280' 2S152-16-P4-01 1-1/4" 1-1/2 230 14 16 420' 3S102-40-P4-01 2" 1 230 3 40 80' 3S102-5-P4-01 1-1/4" 1 230 22 5 600' 2S102-40-P4-01 2" 1 230 3 40 80' 2S152-25-P4-01 1-1/2" 1-1/2 230 9 25 280' 3S152-10-P4-01 1-1/4" 1-1/2 230 21 10 580' 2S102-5-P4-01 1-1/4" 1 230 22 5 600' 3S152-40-P4-01 2" 1-1/2 230 5 40 140' 2S152-10-P4-01 1-1/4" 1-1/2 230 21 10 580' 2S152-40-P4-01 2" 1-1/2 230 5 40 140' 3S152-5-P4-01 1-1/4" 1-1/2 230 31 5 700' 2S152-5-P4-01 1-1/4" 1-1/2 230 31 5 700' S5-10-01 1-1/4" 1/2 9 10 230' S5-16-01 1-1/4" 1/2 5 16 150' S7-16-01 1-1/4" 3/4 8 16 240' S7-25-01 1-1/2" 3/4 5 25 150' S7-10-01 1-1/4" 3/4 12 10 320' S5-25-01 1-1/2" 1/2 3 25 100' S5-5-01 1-1/4" 1/2 13 5 350' S10-16-02 1-1/4" 1 10 16 300' S15-16-01 1-1/4" 1-1/2 14 16 420' S10-25-01 1-1/2" 1 7 25 210' S10-10-01 1-1/4" 1 15 10 400' S15-25-01 1-1/2" 1-1/2 9 25 280' S7-5-01 1-1/4" 3/4 18 5 500' S15-10-01 1-1/4" 1-1/2 21 10 580' S15-40-01 2" 1-1/2 5 40 140' S20-40-01 2" 2 7 40 200' S10-5-01 1-1/4" 1 22 5 600' S20-75-01 2" 2 3 75 100' S20-25-01 1-1/2" 2 11 25 330' S20-16-01 1-1/4" 2 18 16 550' S15-5-01 1-1/4" 1/2 31 5 700' S20-10-01 1-1/4" 2 27 10 750' S30-25-01 1-1/2" 3 15 25 450' S30-16-01 1-1/4" 3 24 16 730' S30-75-01 2" 3 5 75 155' S30-40-01 2" 3 9 40 240' S50-25-01 1-1/2" 5 26 25 790' S30-10-01 1-1/4" 3 34 10 1050' S50-16-01 1-1/4" 5 38 16 1140' S50-40-01 2" 5 15 40 410' S50-75-01 2" 5 8 75 250' S20-5-01 1-1/4" 2 39 5 1030' S75-25-01 1-1/2" 7-1/2 39 25 1170' S100-75-01 2" 10 17 75 525' S75-75-01 2" 7-1/2 12 75 380' S50-10-01 1-1/4" 5 48 10 1310' S75-40-01 2" 7-1/2 25 40 710' S100-40-01 2" 10 30 40 860' PERFORMANCE CURVES DIMENSIONS PUMP PERFORMANCE ORDERING INFORMATION TROUBLESHOOTING SPECIFICATIONS Myers S Series Submersible Well Pump Specifications MANUAL Myers S Series Submersible Well Pump Manual Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers Ranger Series Submersible Well Pumps Buyers Guide & Review

May 28, 2019The Myers Ranger Series 4” high-flow submersible well pumps are perfect for applications requiring a large volume of water. Stainless steel components and high-density composite resin impellers provide exceptional resistance to corrosion in harsh water conditions. The high-torque motor and superior pump hydraulics are carefully matched to handle virtually any job. This is a well pump end only. Please see specifications PDF for motor information. Features High-flow capacities the Ranger 4” sub the easy choice for the really big jobs 300 series stainless steel shell 300 series stainless steel discharge Buna-N discharge bearing Engineered composite impellers resist the corrosive wear from harsh water conditions Engineered composite diffusers Engineered composite suction caps 300 series stainless steel shaft and coupling 300 series stainless steel intake 300 series stainless steel intake screen 300 series stainless steel cable guard 300 series stainless steel fasteners Applications Water systems: Irrigation Industrial Commercial Multiple housing Farm clean water use MYERS RANGER SERIES SUBMERSIBLE WELL PUMPS Model Comparison Chart Model Discharge (NPT) HP Stages GPM Best Efficiency Flow Shut Off Head SS15-50-01 2" 1-1/2 6 50 170' SS10-35-01 2" 1 4 35 100' SS10-25-01 2" 1 7 25 200' SS15-35-01 2" 1-1/2 6 35 170' SS15-25-01 2" 1-1/2 9 25 280' SS20-35-01 2" 2 8 35 220' SS20-80-01 2" 2 6 80 140' SS20-25-01 2" 2 11 25 310' SS30-35-01 2" 3 11 35 310' SS30-25-01 2" 3 15 25 440' SS20-50-01 2" 2 7 50 200' SS30-80-01 2" 3 9 80 210' SS30-50-01 2" 3 10 50 290' SS50-35-01 2" 5 18 35 490' SS50-25-01 2" 5 25 25 750' SS50-80-01 2" 5 14 80 335' SS50-50-01 2" 5 16 50 450' SS75-35-01 2" 7-1/2 28 35 800' SS75-25-01 2" 7-1/2 37 25 1100' SS75-80-01 2" 7-1/2 22 80 520' SS75-50-01 2" 7-1/2 25 50 695' SS100-50-01 2" 10 32 50 1110' SS100-80-01 2" 10 27 80 650' PERFORMANCE CURVES DIMENSIONS PUMP PERFORMANCE SPECIFICATIONS TROUBLESHOOTING SPECIFICATIONS Myers Ranger Series Submersible Well Pump Specifications MANUAL Myers Ranger Series Submersible Well Pump Manual Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers Rustler Series Well Pumps Buyers Guide & Review

May 28, 2019The Myers Rustler series of 4” submersible well pumps is one of the most popular models in the Myers line. They have an exceptional history of durability and trouble-free operation. Stainless steel design and self-lubricating impellers offer the best service for extreme conditions. The Rustler also includes the Pentek XE Series, high-thrust motor for efficient performance and years of extended service. Features 300 series stainless steel shell High-density composite resin discharge Nylatron discharge bearing Engineered composite impellers are self-lubricating and resist abrasion from grit and sand Engineered composite diffusers Engineered composite suction caps 300 series stainless steel shaft and coupling Highdensity composite resin intake screen PVC cable guard Acetal check valve 300 series stainless steel fasteners Built-in eyelet for safety line connection Applications Water systems: Residential Industrial Commercial Multiple housing Farm clean water use MYERS RUSTLER SERIES WELL PUMPS Model Comparison Chart Model Discharge (NPT) HP Voltage Stages GPM Best Efficiency Flow Shut off Head 3NFL51-12-P4-01 1-1/4" 1/2 115 7 12 245' 3NFL52-12-P4-01 1-1/4" 1/2 230 7 12 245' 2NFL52-12-P4-01 1-1/4" 1/2 230 7 12 245' 3NFL52-8-P4-01 1-1/4" 1/2 230 9 8 300' 3NFL52-5-P4-01 1-1/4" 1/2 230 11 5 355' 2NFL51-20-P4-01 1-1/4" 1/2 115 4 20 130' 2NFL52-20-P4-01 1-1/4" 1/2 230 4 20 130' 3NFL72-12-P4-01 1-1/4" 3/4 230 9 12 310' 2NFL52-8-P4-01 1-1/4" 1/2 230 9 8 300' 2NFL51-8-P4-01 1-1/4" 1/2 115 9 8 300' 2S52-10-P4-01 1-1/4" 1/2 230 9 10 230' 3NFL72-20-P4-01 1-1/4" 3/4 230 6 20 200' 2NFL72-12-P4-01 1-1/4" 3/4 230 9 12 310' 2NFL52-5-P4-01 1-1/4" 1/2 230 11 5 355' 2NFL72-20-P4-01 1-1/4" 3/4 230 6 20 200' 3NFL72-8-P4-01 1-1/4" 3/4 230 1 8 400' 3NFL72-5-P4-01 1-1/4" 3/4 230 15 5 500' 3NFL102-20-P4-01 1-1/4" 1 230 8 20 260' 2NFL72-8-P4-01 1-1/4" 3/4 230 12 8 400' 3NFL102-12-P4-01 1-1/4" 1 230 11 12 380' 2NFL102-20-P4-01 1-1/4" 1 230 8 20 260' 2NFL102-12-P4-01 1-1/4" 1 230 11 12 380' 2NFL72-5-P4-01 1-1/4" 3/4 230 15 5 500' 3NFL102-8-P4-01 1-1/4" 1 230 15 8 495' 3NFL102-5-P4-01 1-1/4" 1 230 19 5 630' 2NFL102-8-P4-01 1-1/4" 1 230 15 8 495' 3NFL152-20-P4-01 1-1/4" 1-1/2 230 11 20 355' 2NFL102-5-P4-01 1-1/4" 1 230 19 5 630' 2NFL152-20-P4-01 1-1/4" 1-1/2 230 11 20 355' 2NFL152-8-P4-01 1-1/4" 1-1/2 230 20 8 650' 3NFL152-12-P4-01 1-1/4" 1-1/2 230 16 12 550' 2NFL152-12-P4-01 1-1/4" 1-1/2 230 16 12 550' N520R-01 1-1/4" 1/2 4 20 130' N512R-01 1-1/4" 1/2 7 12 245' N712R-01 1-1/4" 3/4 9 12 310' N55R-01 1-1/4" 1/2 11 5 355' N720R-01 1-1/4" 3/4 6 20 200' N1020R-01 1-1/4" 1 8 20 260' N75R-01 1-1/4" 3/4 15 5 500' N1012R-01 1-1/4" 1 11 12 380' N78R-01 1-1/4" 3/4 12 8 400' N105R-01 1-1/4" 1 19 5 630' N1520R-01 1-1/4" 1-1/2 11 20 355' N108R-01 1-1/4" 1 15 8 495' N1512R-01 1-1/4" 1-1/2 16 12 550' PERFORMANCE CURVES DIMENSIONS PUMP PERFORMANCE CABLE SELECTION TROUBLESHOOTING SPECIFICATIONS Myers Rustler Series Well Pump Specifications MANUAL Myers Rustler Series Well Pump Manual Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers Predator Plus ST Series Well Pumps Buyers Guide & Review

May 28, 2019The Myers Predator Plus ST series 4” submersible well pumps have a proven track record for reliability and performance, and are the preferred brand by many industry professionals. Stainless steel construction and self-lubricating impellers provide reliable performance under the most demanding conditions. The Predator Plus also features the Pentek XE Series, high-thrust motor for increased efficiency and extended service life. Features 300 series stainless steel shell 300 series stainless steel discharge Nitrile rubber discharge bearing Self-lubricating engineered composite impellers resist abrasion from grit and sand Teflon impregnated staging proven to outlast the competition Engineered composite diffusers Engineered composite suction caps 300 series stainless steel shaft and coupling 300 series stainless steel intake 300 series stainless steel intake screen 300 series stainless steel cable guard Spring loaded internal check valve 304 series stainless steel fasteners All stainless steel is lead-free Features the highthrust Pentek XE motor for the ultimate in power, efficient performance and longer life Thermal overload and lightning protected Field serviceable, threaded pump assembly Built-in eyelet for safety line connection Applications Water systems: Residential Industrial Commercial Multiple housing Farm clean water use MYERS PREDATOR PLUS ST SERIES WELL PUMPS Model Comparison Chart Model Discharge (NPT) HP Voltage Stages Best Efficiency GPM Shut Off Head 2ST51-12PLUS-P4-2 1-1/4" 1/2 115 7 12 250' 3ST51-12PLUS-P4-2 1-1/4" 1/2 115 7 12 250' 3ST52-12PLUS-P4-2 1-1/4" 1/2 230 7 12 250' 3ST51-8PLUS-P4-2 1-1/4" 1/2 115 9 8 300' 3ST52-8PLUS-P4-2 1-1/4" 1/2 230 9 8 300' 3ST51-5PLUS-P4-2 1-1/4" 1/2 115 11 5 360' 3ST52-5PLUS-P4-2 1-1/4" 1/2 230 11 5 360' 3ST51-20PLUS-P4-2 1-1/4" 1/2 115 4 20 130' 3ST52-20PLUS-P4-2 1-1/4" 1/2 230 4 20 130' 2ST52-12PLUS-P4-2 1-1/4" 1/2 230 7 12 250' 3ST72-12PLUS-P4-2 1-1/4" 3/4 230 9 12 310' 2ST51-8PLUS-P4-2 1-1/4" 1/2 115 9 8 300' 2ST52-8PLUS-P4-2 1-1/4" 1/2 230 9 8 300' 3ST72-20PLUS-P4-2 1-1/4" 3/4 230 6 20 200' 2ST51-20PLUS-P4-2 1-1/4" 1/2 115 4 20 130' 2ST52-20PLUS-P4-2 1-1/4" 1/2 230 4 20 130' 2ST72-12PLUS-P4-2 1-1/4" 3/4 230 9 12 310' 2ST72-20PLUS-P4-2 1-1/4" 3/4 230 6 20 200' 3ST72-8PLUS-P4-2 1-1/4" 3/4 230 12 8 390' 2ST51-5PLUS-P4-2 1-1/4" 1/2 115 11 5 360' 2ST52-5PLUS-P4-2 1-1/4" 1/2 230 11 5 360' 3ST102-20PLUS-P4-2 1-1/4" 1 230 8 20 270' 3ST72-5PLUS-P4-2 1-1/4" 3/4 230 15 5 500' 3ST102-12PLUS-P4-2 1-1/4" 1 230 11 12 380' 2ST72-8PLUS-P4-2 1-1/4" 3/4 230 12 8 390' 2ST102-20PLUS-P4-2 1-1/4" 1 230 8 20 270' 2ST102-12PLUS-P4-2 1-1/4" 1 230 11 12 380' 3ST102-8PLUS-P4-2 1-1/4" 1 230 15 8 490' 2ST72-5PLUS-P4-2 1-1/4" 3/4 230 15 5 500' 3ST102-5PLUS-P4-2 1-1/4" 1 230 19 5 610' 2ST102-5PLUS-P4-2 1-1/4" 1 230 19 5 610' 2ST102-8PLUS-P4-2 1-1/4" 1 230 15 8 490' 2ST152-20PLUS-P4-2 1-1/4" 1-1/2 230 11 20 360' 3ST152-20PLUS-P4-2 1-1/4" 1-1/2 230 11 20 360' 3ST152-12PLUS-P4-2 1-1/4" 1-1/2 230 16 12 580' 2ST152-8PLUS-P4-2 1-1/4" 1-1/2 230 20 8 650' 3ST152-8PLUS-P4-2 1-1/4" 1-1/2 230 20 8 650' 3ST152-5PLUS-P4-2 1-1/4" 1-1/2 230 26 5 860' 2ST152-12PLUS-P4-2 1-1/4" 1-1/2 230 16 12 380' 2ST152-5PLUS-P4-2 1-1/4" 1-1/2 230 26 5 860' ST5-20PLUS-2 1-1/4" 1/2 4 20 130' N58R-01 1-1/4" 1/2 9 8 300' ST5-12PLUS-2 1-1/4" 1/2 7 12 250' ST7-12PLUS-2 1-1/4" 3/4 9 12 310' ST5-8PLUS-2 1-1/4" 1/2 9 8 300' ST5-5PLUS-2 1-1/4" 1/2 11 5 360' ST7-20PLUS-2 1-1/4" 3/4 6 20 200' ST10-12PLUS-2 1-1/4" 1 11 12 380' ST7-8PLUS-2 1-1/4" 3/4 12 8 390' ST10-20PLUS-2 1-1/4" 1 8 20 270' ST7-5PLUS-2 1-1/4" 3/4 15 5 500' ST10-8PLUS-2 1-1/4" 1 15 8 490' ST10-5PLUS-2 1-1/4" 1 19 5 610' ST15-20PLUS-2 1-1/4" 1-1/2 11 20 360' ST15-12PLUS-2 1-1/4" 1-1/2 16 12 380' ST15-8PLUS-2 1-1/4" 1-1/2 20 8 650' ST15-5PLUS-2 1-1/4" 1-1/2 26 5 860' PERFORMANCE CURVES DIMENSIONS CABLE SELECTION PUMP PERFORMANCE TROUBLESHOOTING SPECIFICATIONS Myers Predator Plus ST Series Well Pump Specifications MANUAL Myers Predator Plus ST Series Well Pump Manual Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Zoeller Shallow and Convertible Deep Well Jet Pumps Buyers Guide & Review

April 25, 2019Zoeller shallow well and convertible deep well jet pumps feature sturdy construction, corrosion resistance, easy serviceability, and excellent performance. Well pumps are used to deliver water from a well to a home that is not connected to a municipal water supply. They are also commonly used for small-scale irrigation and livestock watering. Well pumps are available in shallow, deep well convertible, and submersible designs. Jet well pumps are surface pumps configured above the well system, while a jet assembly system (twin pipe or Packer depending on the application) is inserted into the well shaft. The main components of a jet pump are a nozzle, venturi, and the jet itself. The pumps components work together to create a vacuum above the water, which allows atmospheric pressure underneath to push the water upwards. Jet pumps can be either horizontally or vertically configured and are much the same size and shape as other pumps. Features Cast iron shallow well jet pumps Sturdy, cast iron construction Includes removable ejector for easy serviceability Includes pressure switch Thermal overload protects against overheating Special priming port and large volume case makes priming easier Continuous duty, uni-frame, 56 frame motor (NEMA J adaptable) Capacitor start motors provide maximum starting torque Stainless steel motor shaft sleeve for corrosion-resistance Easy access drain plug for winterizing Carbon/ceramic mechanical shaft seal Cast iron convertible deep well jet pumps with power plus 56 frame motor Sturdy, cast iron construction Highly serviceable NEMA J or NEMA J adaptable motors Includes pressure switch Thermal overload protects against overheating Ejector purchased separately ZOELLER SHALLOW & CONVERTIBLE DEEP WELL JET PUMPS Model Comparison Chart Model Discharge Suction HP Voltage Phase NE460 3/4" 1-1/4" 1/2 115/230 1 NE461 3/4" 1-1/4" 3/4 115/230 1 NE462 3/4" 1-1/4" 1/2 115/230 1 NE463 3/4" 1-1/4" 1 115/230 1 DIAGRAM CAPACITIES REPLACEMENT PARTS TROUBLESHOOTING BROCHURE Zoeller Shallow and Convertible Deep Well Jet Pumps Brochure OWNERS MANUAL Zoeller Shallow and Convertible Deep Well Jet Pumps Owner's Manual Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Goulds HS Series Submersible Well Pumps Buyers Guide & Review

April 17, 2019Goulds Submersible Well Pumps features the HS series is designed for use in minimum 4" diameter water wells. Each pump end below is close coupled to a premium Centripro motor. The HS series features premium quality construction materials for efficient performance and long service life. A key feature of this series is the quad lock technology, in which four roll formed grooves provide durability, tested to exceed the strength of poly and PVC pipes. The Goulds Submersible Well Pump, HS series pumps feature a Nylon discharge head with a built-in or-ring seal check valve that can be removed easily. The impellers are composite engineered Noryl and the diffusers are Lexan for excellent abrasion resistance, with all non-metallic parts being non-toxic, non-leaching, and FDA compliant. The floating impeller stack provides superior sand handling and durability. The motor adapter is Nylon while the hex design shafts, shaft couplings, casings, and stage bowls are corrosion resistant stainless steel. Complete pump and motor assemblies are CSA listed, while CSA/CUS approved motors are available in both 2-wire and 3-wire single phase designs. GOULDS WELL PUMP HS SERIES Model Comparison Chart Model Discharge HP Voltage Phase Best Efficiency GPM Wire Stages 10HS05421C 1-1/4" NPT 1/2 115 1 10 2-Wire 7 10HS05422C 1-1/4" NPT 1/2 230 1 10 2-Wire 7 7HS05422C 1-1/4" NPT 1/2 230 1 7 2-Wire 10 7HS05421C 1-1/4" NPT 1/2 115 1 7 2-Wire 10 10HS07422C 1-1/4" NPT 3/4 230 1 10 2-Wire 10 5HS05421C 1-1/4" NPT 1/2 115 1 5 2-Wire 12 5HS05422C 1-1/4" NPT 1/2 230 1 5 2-Wire 12 18HS07422C 1-1/4" NPT 3/4 230 1 18 2-Wire 6 7HS07422C 1-1/4" NPT 3/4 230 1 7 2-Wire 13 10HS10422C 1-1/4" NPT 1 230 1 10 2-Wire 12 18HS10422C 1-1/4" NPT 1 230 1 18 2-Wire 8 25HS10422C 1-1/4" NPT 1 230 1 25 2-Wire 7 5HS07422C 1-1/4" NPT 3/4 230 1 5 2-Wire 15 7HS10422C 1-1/4" NPT 1 230 1 7 2-Wire 17 5HS10422C 1-1/4" NPT 1 230 1 5 2-Wire 20 25HS15422C 1-1/4" NPT 1-1/2 230 1 25 2-Wire 9 18HS15422C 1-1/4" NPT 1-1/2 230 1 18 2-Wire 11 10HS15422C 1-1/4" NPT 1-1/2 230 1 10 2-Wire 17 PERFORMANCE RATINGS BREAKDOWN DIAGRAM MATERIALS OF CONSTRUCTION MOTOR INFORMATION DIMENSIONS AND WEIGHTS NOMENCLATURE GUIDE BROCHURE Goulds HS Series Well Pump Brochure TECHNICAL BROCHURE Goulds HS Series Submersible Well Pump Technical Brochure INSTALLATION MANUAL Goulds Centripro Motor Application and Installation Data Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Goulds GS Series Submersible Well Pumps Buyers Guide & Review

April 17, 2019The Goulds GS is part of the Submersible Well Pump Series which is designed for use in minimum 4" diameter water wells. Each pump end below is close coupled to a premium Centripro motor. Designed with a stainless steel construction for strength and corrosion resistance, these pumps feature two cast-in safety line loops for installer convenience. Submersible Well Pump Series, GS pumps are built for dependable operation and long service life. The casing is corrosion resistant stainless steel, the impellers are Noryl and the diffusers are Lexan for excellent abrasion resistance, with all non-metallic parts being non-toxic and FDA compliant. The floating impeller stack provides superior sand handling and durability, while proprietary engineering polymer bearing provides additional abrasion and wear resistance. The enclosed upper bearing is mounted in a durable Noryl bearing spider for excellent abrasion resistance. The discharge head also includes a built-in stainless steel check valve. The motor shaft has a six sided hex shaft design for positive impeller drive, while the motor adapter is Cast 303 stainless steel for rigid/accurate alignment while providing easy access to motor mounting nuts using a standard open end wrench. The motor is powered for continuous operation within the motor limits without damage. In general, the GS series units are easily field serviceable with common tools and readily available Goulds Pump Repair Parts. Please note that 3-Wire pumps require a control box for operation. Control box sold separately. GOULDS GS SERIES WELL PUMP Model Comparison Chart Model Discharge HP Voltage Phase Best Efficiency GPM Wire Stages 10GS05412RCL 1-1/4" NPT 1/2 230 1 10 3-Wire 5 10GS05411RCL 1-1/4" NPT 1/2 115 1 10 3-Wire 5 10GS05411CL 1-1/4" NPT 1/2 115 1 10 3-Wire 7 10GS05412CL 1-1/4" NPT 1/2 230 1 10 3-Wire 7 10GS05421RC 1-1/4" NPT 1/2 115 1 10 2-Wire 5 10GS05422RC 1-1/4" NPT 1/2 230 1 10 2-Wire 5 10GS05421C 1-1/4" NPT 1/2 115 1 10 2-Wire 7 10GS05422C 1-1/4" NPT 1/2 230 1 10 2-Wire 7 7GS05412RCL 1-1/4" NPT 1/2 230 1 7 3-Wire 7 7GS05411RCL 1-1/4" NPT 1/2 115 1 7 3-Wire 7 13GS05412CL 1-1/4" NPT 1/2 230 1 13 3-Wire 5 13GS05411CL 1-1/4" NPT 1/2 115 1 13 3-Wire 5 7GS05412CL 1-1/4" NPT 1/2 230 1 7 3-Wire 10 7GS05411CL 1-1/4" NPT 1/2 115 1 7 3-Wire 10 7GS05421RC 1-1/4" NPT 1/2 115 1 7 2-Wire 7 7GS05422RC 1-1/4" NPT 1/2 230 1 7 2-Wire 7 13GS05421C 1-1/4" NPT 1/2 115 1 13 2-Wire 5 13GS05422C 1-1/4" NPT 1/2 230 1 13 2-Wire 5 5GS05411RCL 1-1/4" NPT 1/2 115 1 5 3-Wire 9 5GS05412RCL 1-1/4" NPT 1/2 230 1 5 3-Wire 9 7GS05421C 1-1/4" NPT 1/2 115 1 7 2-Wire 10 7GS05422C 1-1/4" NPT 1/2 230 1 7 2-Wire 10 5GS05412CL 1-1/4" NPT 1/2 230 1 5 3-Wire 12 5GS05411CL 1-1/4" NPT 1/2 115 1 5 3-Wire 12 5GS05421RC 1-1/4" NPT 1/2 115 1 5 2-Wire 9 5GS05422RC 1-1/4" NPT 1/2 230 1 5 2-Wire 9 10GS07412CL 1-1/4" NPT 3/4 230 1 10 3-Wire 14 18GS07412CL 1-1/4" NPT 3/4 230 1 18 3-Wire 6 13GS07412CL 1-1/4" NPT 3/4 230 1 13 3-Wire 7 5GS05421C 1-1/4" NPT 1/2 115 1 5 2-Wire 12 5GS05422C 1-1/4" NPT 1/2 230 1 5 2-Wire 12 10GS07422C 1-1/4" NPT 3/4 230 1 10 2-Wire 10 7GS07412CL 1-1/4" NPT 3/4 230 1 7 3-Wire 7 18GS07422C 1-1/4" NPT 3/4 230 1 18 2-Wire 6 25GS10412CL 1-1/4" NPT 1 230 1 25 3-Wire 7 13GS07422C 1-1/4" NPT 3/4 230 1 13 2-Wire 7 18GS10412CL 1-1/4" NPT 1 230 1 18 3-Wire 8 13GS10412CL 1-1/4" NPT 1 230 1 13 3-Wire 10 10GS10412CL 1-1/4" NPT 1 230 1 10 3-Wire 12 7GS07422C 1-1/4" NPT 3/4 230 1 7 2-Wire 13 25GS10422C 1-1/4" NPT 1 230 1 25 2-Wire 7 18GS10422C 1-1/4" NPT 1 230 1 18 2-Wire 8 5GS07412CL 1-1/4" NPT 3/4 230 1 5 3-Wire 15 13GS10422C 1-1/4" NPT 1 230 1 13 2-Wire 10 10GS10422C 1-1/4" NPT 1 230 1 10 2-Wire 12 7GS10412CL 1-1/4" NPT 1 230 1 7 3-Wire 17 5GS07422C 1-1/4" NPT 3/4 230 1 5 2-Wire 15 25GS15412CL 1-1/4" NPT 1-1/2 230 1 25 3-Wire 9 7GS10422C 1-1/4" NPT 1 230 1 7 2-Wire 17 18GS15412CL 1-1/4" NPT 1 230 1 18 3-Wire 11 5GS10412CL 1-1/4" NPT 1 230 1 5 3-Wire 20 13GS15412CL 1-1/4" NPT 1-1/2 230 1 13 3-Wire 12 10GS15412CL 1-1/4" NPT 1-1/2 230 1 10 3-Wire 17 5GS10422C 1-1/4" NPT 1 230 1 5 2-Wire 20 25GS15422C 1-1/4" NPT 1-1/2 230 1 25 2-Wire 9 7GS15412CL 1-1/4" NPT 1-1/2 230 1 7 3-Wire 22 18GS15422C 1-1/4" NPT 1-1/2 230 1 18 2-Wire 11 13GS15422C 1-1/4" NPT 1-1/2 230 1 13 2-Wire 12 25GS20412CL 1-1/4" NPT 2 230 1 25 3-Wire 11 18GS20412CL 1-1/4" NPT 2 230 1 18 3-Wire 14 10GS15422C 1-1/4" NPT 1-1/2 230 1 10 2-Wire 17 13GS20412CL 1-1/4" NPT 2 230 1 13 3-Wire 14 10GS20412CL 1-1/4" NPT 2 230 1 10 3-Wire 14 7GS15422C 1-1/4" NPT 1-1/2 230 1 7 2-Wire 22 5GS15412CL 1-1/4" NPT 1-1/2 230 1 5 3-Wire 26 5GS15422C 1-1/4" NPT 1-1/2 230 1 5 2-Wire 26 7GS20412CL 1-1/4" NPT 2 230 1 7 3-Wire 14 25GS30412CL 1-1/4" NPT 3 230 1 25 3-Wire 15 18GS30412CL 1-1/4" NPT 3 230 1 18 3-Wire 19 13GS30412CL 1-1/4" NPT 3 230 1 13 3-Wire 21 5GS20412CL 1-1/4" NPT 2 230 1 5 3-Wire 14 10GS30412CL 1-1/4" NPT 3 230 1 10 3-Wire 27 7GS30412CL 1-1/4" NPT 3 230 1 7 3-Wire 34 25GS50412RCL 1-1/4" NPT 5 230 1 25 3-Wire 22 18GS50412RCL 1-1/4" NPT 5 230 1 18 3-Wire 24 25GS50412CL 1-1/4" NPT 5 230 1 25 3-Wire 26 18GS50412CL 1-1/4" NPT 5 230 1 18 3-Wire 30 10GS50412RCL 1-1/4" NPT 5 230 1 10 3-Wire 35 10GS50412CL 1-1/4" NPT 5 230 1 10 3-Wire 42 PERFORMANCE RATINGS BREAKDOWN DIAGRAMS DIMENSIONS INSTALLATION MATERIALS OF CONSTRUCTION MOTOR INFORMATION REPAIR PARTS NOMENCLATURE GUIDE BROCHURE Goulds GS Series Submersible Well Pump Brochure SPECIFICATIONS Goulds GS Series Submersible Well Pump Brochure INSTALLATION MANUAL Goulds GS Series Submersible Well Pump Installation Manual REPAIR PARTS Goulds GS Series Submersible Well Pump Repair Parts (Pumps Built 02/2003-07/2005) Goulds GS Series Submersible Well Pump Repair Parts (Pumps Built After 07/2005) Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Goulds JRS Series Shallow Well Jet Pumps Buyers Guide & Review

April 12, 2019The Goulds JRS Shallow Well Pump series is deal for use in homes, cottages, and for general booster service applications. Each JRS pump has an integral shallow well jet built into the casing, eliminating the need for a separate shallow well adapter. Another key feature of the Goulds JRS Shallow Well Pump is the air handling ability - after the initial prime, the pump can re-prime itself even when air gets into the system. Pumping will simply resume as soon as the water level rises above the foot valve. In addition, the pump is powered for continuous operation within the motor limits, corrosion resistant (with baked on electro-coat paint), and easy to service, featuring a nozzle clean-out plug and back pull-out design. The corrosion resistant engineered plastic tubing and fittings are also easily removed for cleaning. A drain plug is included for ease of winterizing and maintenance. The seal housing is an engineered composite, the impeller is glass filled Noryl, and the guidevane diffuser is injection molded, food grade, glass filled Lexan. The NEMA standard motor is a capacitor start type with a stainless steel shaft and a built-in overload with automatic reset. The basic unit includes the pump with integral shallow well jet (nozzle and venturi), motor, pressure switch, and tubing. GOULDS JRS SHALLOW WELL JET PUMP Model Comparison Chart Model Suction Discharge HP Voltage Phase GPM JRS5H 1-1/4" NPT 1" NPT 1/2 115/230 1 6.4 @ 5' (30 PSI) JRS524 1-1/4" NPT 1" NPT 1/2 115/230 1 13.3 @ 5' (30 PSI) JRS5 1-1/4" NPT 1" NPT 1/2 115/230 1 13.3 @ 5' (30 PSI) JRS5LT 1-1/4" NPT 1" NPT 1/2 115/230 1 13.3 @ 5' (30 PSI) JRS7 1-1/4" NPT 1" NPT 3/4 115/230 1 22.5 @ 5' (30 PSI) JRS10 1-1/4" NPT 1" NPT 1 115/230 1 27 @ 5' (30 PSI) PERFORMANCE RATINGS COMPONENTS INSTALLATION DIMENSIONS AND WEIGHTS REPAIR PARTS BROCHURE Goulds JRS Shallow Well Jet Pump Brochure INSTALLATION MANUAL Goulds JRS Shallow Well Jet Pump Installation Manual REPAIR PARTS Goulds JRS Shallow Well Jet Pump Repair Parts Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Goulds BF03S Shallow Well Jet Pumps Buyers Guide & Review

April 12, 2019The Goulds BF03S Shallow Well Jet Pump is specifically designed for water transfer in small homes, camps, and mobile homes. This compact and tankless pump can easily be installed in a variety of spaces and features a self-adjusting capacity that automatically adjusts to water demand. Another key feature of the Goulds BF03S Jet Pump is the air handling ability - when the pump is primed, it never needs priming again even if the water level drops below the end of the suction pipe. The BF03S will simply start pumping as soon as the water level rises again. Gas or air in the water will not air-bind the pump. In addition, the pump is powered for continuous operation within the motor limits, corrosion resistant (with baked on electro-coat paint), and easy to service, featuring a nozzle clean-out plug and back pull-out design. The NEMA standard motor is a capacitor start type with a stainless steel shaft and a built-in overload with automatic reset. The unit package includes the pump, motor, AS3 (20-40) pressure switch, tubing, fittings, air volume control valve, suction check valve, nozzle, and diffuser. GOULDS BF03S SHALLOW WELL JET PUMP Model Comparison Chart Model Discharge HP Voltage Phase GPM Max. Suction Lift BF03S 23/4" NPT 1/2 115/230 1 8.8 @ 20 PSI 25' PERFORMANCE RATINGS COMPONENTS INSTALLATION DIAGRAM REPAIR PARTS BROCHURE Goulds BF03S Shallow Well Jet Pump Brochure INSTALLATION INSTRUCTIONS Goulds BF03S Shallow Well Jet Pump Installation Instructions SERVICE MANUAL Goulds BF03S Shallow Well Jet Pump Service Manual REPAIR PARTS Goulds BF03S Shallow Well Jet Pump Repair Parts Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

How does a Pressure Switch Work?

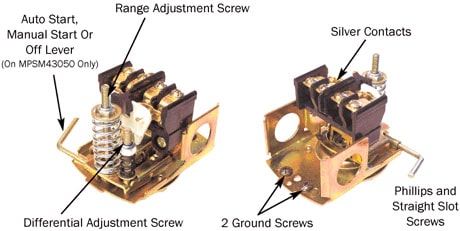

January 9, 2019Welcome to Inspector Pumphead’s classroom. This is the place where the Inspector likes to teach everything he knows about all the parts and components that makeup pumps! This is also the place where he likes to talk about himself in the third person. In this week’s edition the Inspector will be discussing what a pressure switch is and how they operate. The Inspector would also like to point out that if you ever inspect your pressure switch, always make sure the power to it is OFF for safety’s sake. Pressure switches are commonly associated with well pumps. Well pumps deliver the clean water to your house that you use for drinking, watering the garden, and loading the unnecessarily-large-but-you-can-never-have-too-much-firepower Super Soaker that you terrorize your neighbors with. What, just me But the Inspector digresses... To put it in a nutshell, pressure switches basically tell the pump when to turn on and when to turn off. A more technical definition of a pressure switch sounds like this: a device that monitors pressure and provides an output when a set pressure is reached. The specific pressure that opens and closes the switch is called the set point. Many residential pressure switches are designed for a minimum of 30 PSI and a maximum of 50 PSI (or pounds per square inch). So in this example when the pressure in the system drops to 30 PSI, the switch activates and lets more water flow into the system. At 50 PSI, the switch turns off. Pressure switches are comprised of several components including an adjustment screw, diaphragm, lever, and contacts. The adjustment screw sets the spring pressure. This can be adjusted to change the on-and-off pressure range that the switch operates at. The standard range of a pressure switch is usually located on the unit itself or on the box it comes in. You can always check online as well if you know the model number. Pressure switches rely on water pressure to do all the work. The change in pressure that activates the switch is provided via the water from the well. The pressure moves up through the diaphragm which presses against a piston and spring, which in turn opens or closes the contacts. Open contacts located within the switch, closes when pressure drops. This completes an electrical circuit, which in turn activates the pump. When the set pressure is reached, this allows the contacts to open again which turns off the pump. Pressure switches are usually wired to a control box. Wires from the box are connected to separate terminals within the switch while other terminals are connected to a power supply. If you have any questions about pressure switches or if you’re in need of a replacement, you can give our pressure switch page a look or give a call to one of our PumpProducts.com application engineers. They’re waiting for your call and would be happy to help you figure out which pressure switch is right for your application. They have been personally trained by the Inspector so they know what they’re talking about! Check in next time to the Inspector’s classroom where he will be getting into pressure switch troubleshooting, adjusting, and maintenance tips! Pump Products applications engineers are standing by to help you find the right pump, as well as to provide price quotes, availability and shipping information. Call our toll free number 1-800-429-0800.