-

Myers AG Series Agricultural Sewage Pumps Buyers Guide & Review

January 30, 2018The Myers AG series agricultural sewage pumps are designed specifically for use in agricultural lagoon and sewage pit applications. These pumps are constructed to handle stringy trash, fibrous waste, slurries and other difficult materials without damaging the recessed vortex style impeller. $(document).ready(function(){ $("td").css("border", "1px solid black") }); This pump comes featured in both a 3 HP and 5 HP variations, with either being able to pass 3" solids. All pumps are made of durable, heavy duty cast iron with a powder coated finish to prevent corrosion and the buildup of salt crystals. In addition, the motor is equipped with thermal overload protection, automatic reset and dual shaft seals with seal leak probe for maximum protection against interference. The Myers AG series pumps are also equipped with leg stands and a lifting handle for simple installation. Please note that Myers AG pumps are special order pumps not listed on our website. Be sure to call and talk to one of our pump experts to order one of these exceptional pumps at 1-800-429-0800. Myers AG Series Agricultural Sewage Pumps Model Comparison Chart Model HP Volt. Ph. FLA Solids Lbs. RPM AG3 3 230 1 195 3" 200 1750 AG5 5 230 1 195 3" 210 1750 PERFORMANCE CURVE BREAKDOWN DIAGRAM DIMENSIONS BROCHURE Myers AG Series Brochure MANUAL Myers AG Series Manual Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers AG Series Agricultural Sewage Pumps Buyers Guide & Review

January 29, 2018In this video, Pump Products highlights the Myers AG series agricultural sewage pump. This pump series is well-suited to pumping wastewater in agricultural applications. Video includes all relevant features, specifications and benefits. This is a special order item, so be sure to call us for more information. Pump Products' applications engineers are happy to work with customers to figure out the right pump for your application and budget. Call 1800-429-0800 to speak to an expert. Subscribe to our channel for more how-to guides, product highlights and general information about pumps.

-

Inspector Pumphead’s Quick Tips: Do Not Dry Run a Centrifugal Pump

January 26, 2018Here’s another minty-fresh edition of everyone’s favorite semi-recurring content feature: Inspector Pumphead’s Quick Tips! In this space, I, Inspector Pumphead from Pump Products, will be sending out friendly reminders and dispensing basic tips for ordering, maintaining and servicing pumps. The Inspector is in and here to help! Quick Tip: Dry running a centrifugal pump can cause damage to your pump and system. A centrifugal pump uses the kinetic energy generated by the rotation of the impeller to transport water. Keep in mind that most of the pumps we sell are centrifugal pumps. The liquid that the pump transports is key to counteracting the heat generated by the impeller's motion and keeping both the pump body and motor cool. When and if the pump is run dry, there is no water to counter and slow the motion of the impeller. Speed increases past the desired point and the heat generated increases as well. This could cause sparking, overheating, melted plastic and a busted pump that needs immediate replacement. We've heard plenty of horror stories of warped pumps that were run dry for one reason or another. So make sure to periodically check your pump and make sure that the water is flowing smoothly and consistently to your pump. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers HR50 Convertible Jet Pumps Buyers Guide & Review

January 26, 2018Welcome back to Inspector Pumphead Recommends! In this feature, I will be recommending a specific pump model and highlighting the features, specifications, and benefits of this pump. It could be a new product, a best seller, a seasonally appropriate pump or one that is strongly recommended by the application engineers. Let's dive in! Myers HR505 Shallow Well Jet Pump Today I am highlighting the Myers HR50 convertible well jet pump. The Myers HR50 pump is a jet pump typically used for well service in residential homes, farms and even in commercial/industrial applications. $(document).ready(function(){ $("td").css("border", "1px solid black") }); As a convertible jet pump, the HR50 type can be used for either shallow well (less than 25 ft.) or deep well (25 ft. or more) applications with the proper fittings. Pump Products carries both subtypes as complete units, the HRD50S for shallow well applications and the HR50D for deep well applications. Please note that for new deep well installations, a jet assembly package or Packer style package must be purchased separately. Construction The Myers HR50 has a cast iron pump case with a precision molded polycarbonite impeller and a mixed ceramic/stainless steel shaft seal. The motor is dual ball-bearing with a voltage selector switch (115/230) in a dual compartment. The diffuser includes a stainless steel wear ring. A square D pressure switch with adjustable on/off settings is included, as is a priming screen. Typical Shallow Well Installation Typical Deep Well Installation Specs Model Disch. HP Voltage Phase GPM Max. Head Cord PSI HR50 1.25" NPT 1/2 115/230 1 16 160' 15' 70 Curve Dimensions LITERATURE Myers HR Series Brochure Myers HR Series Manual Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers HR Series Convertible Jet Pumps Buyers Guide & Review

January 26, 2018In this video, Pump Products highlights the Myers HR series convertible well jet pump. This pump series is well-suited to either shallow well or deep well applications with the proper fittings. Video includes all relevant features, specifications and benefits. View the product listings here: https://www.pumpproducts.com/myers-hr... Pump Products' applications engineers are happy to work with customers to figure out the right pump for your application and budget. Call 1800-429-0800 to speak to an expert. Subscribe to our channel for more how-to guides, product highlights and general information about pumps.

-

Pump Products Now Distributing Goulds Premium Efficiency Pumps

January 24, 2018PumpProducts.com has had a long and fruitful partnership with Goulds Water Technology Pumps and we are proud to add to that rich tradition. PumpProducts.com is excited to announce that we are now distributing Goulds Centrifugals with premium efficiency motors. Specifically, PumpProducts.com now has the right to distribute Goulds 3657 Series Centrifugal Pumps. These high quality pumps are typically used for pure water transfer, chemical transfer, pharmaceutical procedures, and beverage processing. The stainless steel casings prevent corrosion and the compact, sensible frame mounted design allows for easy installation in a variety of application settings. Gould advertises the "superior materials of construction" which includes precision investment cast 316 stainless steel with NPT threaded suction and discharge with four position discharge orientation. The open impeller design reduces the risk of clogging. The mechanical seal has carbon vs silicon carbide seal faces encased in Viton elastomers with stainless steel parts (optional seals can also be obtained for high temp or abrasive applications). The Goulds 3657 Centrifugal Pumps are also built with a back pull-out design for simple cleaning and disassembly without disturbing the piping. The premium efficiency motor is a NEMA standard 56J frame with a ball bearing design that allows for continuous operation. Both single and three phase models are available. Overall, the pumping ability of this series is hard to match. "It's a great deal for the customer and all of us here were excited to able to sell these top-of-the-line pumps," PumpProducts.com application engineer Lee says. "Goulds always delivers with high quality products." PumpProducts.com application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability, and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Goulds 45HB/70HB Series Booster Pumps Buyers Guide & Review

January 23, 2018The Goulds 45HB and 70HB series Booster Pumps are multi-stage pumps designed to offer steady, quiet and vibration free boosting service for years. Each pump comes with a variety of stages, with the impellers and diffusers made of precision molded glass filled thermoplastic and 300 series stainless bowls with positive alignment (no gaskets required). The motor is close coupled to the pump and the ball bearings carry all radial and axial thrust loads, making these pumps perfect for continuous operation over a number of years. All pump casings are stainless steel. Commons application settings for 45HB and 70HB Booster Pumps include high rise buildings, multiple dwelling buildings, high pressure cleaning and spraying systems, reverse osmosis systems and general booster service. The maximum inlet pressure is 100 PSI and the maximum operating temperature is 160°F. Please note that as these are booster pumps, they have no lift capability and should not be run dry. Do not deadhead the pumps. Goulds 45HB/70HB Series Model Comparison Chart Model Disch. HP Volt. Phase GPM Head Stages 70HB13035PE 2" NPT 3 208-230/460 3 100 145' 2 45HB13035PE 2" NPT 3 208-230/460 3 68 225' 3 70HB23035PE 2" NPT 3 208-230/460 3 100 145' 2 45HB23035PE 2" NPT 3 208-230/460 3 68 150' 2 70HB15035PE 2" NPT 5 208-230/460 3 100 255' 4 70HB13012 2" NPT 3 115/208-230 1 100 145' 2 45HB13012 2" NPT 3 115/208-230 1 68 225' 3 45HB15035PE 2" NPT 5 208-230/460 3 68 375' 5 70HB25035PE 2" NPT 5 208-230/460 3 100 202' 3 45HB25035PE 2" NPT 5 208-230/460 3 68 312' 4 45HB17535PE 2" NPT 7.5 208-230/460 3 68 525' 7 70HB17535PE 2" NPT 7.5 208-230/460 3 100 400' 6 70HB23012 2" NPT 3 115/208-230 1 100 145' 2 45HB23012 2" NPT 3 115/208-230 1 100 150' 2 70HB15013 2" NPT 5 208-230 1 100 255' 4 45HB15013 2" NPT 5 208-230 1 68 375' 5 70HB27535PE 2" NPT 7.5 208-230/460 3 100 348' 5 45HB27535PE 2" NPT 7.5 208-230/460 3 68 450' 6 70HB21135PE 2" NPT 10 208-230/460 3 100 475' 7 45HB11135PE 2" NPT 10 208-230/460 3 68 760' 7 70HB11135PE 2" NPT 10 208-230/460 3 100 600' 9 45HB21135PE 2" NPT 10 208-230/460 3 68 612' 8 70HB17513 2" NPT 7.5 208-230/460 1 100 400' 6 70HB25013 2" NPT 5 208-230 1 100 202' 3 45HB25013 2" NPT 5 208-230 1 68 312' 4 45HB17513 2" NPT 7.5 208-230 1 68 525' 7 PERFORMANCE CURVES MOTOR DIMENSIONS BROCHURE Goulds HB Series Brochure MANUAL Goulds HB Series Instruction Manual SPECIFICATIONS No Specifications Sheet Available REPAIR PARTS Goulds HB Series Repair Parts List Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers 3RMW Series Sewage Pumps Buyers Guide & Review

January 19, 2018The Myers 3RMW series sewage pumps are submersible vortex wastewater pumps designed specifically to pump fibrous or stringy solids. These Myers pumps provide smooth, vibration and cavitation free performance no matter the system requirements. Features include a cast iron motor, recessed ductile iron impeller that reduces radial load and increases bearing life, oil-filled motor, heat sensor thermostats, seal leak probes and pump out vanes on the impeller. Available in both 1750 RPM and 3450 RPM models and/or single seal/dual seal variations. All pumps listed below are manually operated and include a standard 20 ft. power cord jacket sealed with compression fittings and potted with epoxy to prevent wicking. MYERS 3RMW SERIES SEWAGE PUMPS Model Comparison Chart Model Disch. HP Volt. Ph. GPM Head Seal RPM 3RMW15M2-43 3" Fl. Horiz. 1.5 460 3 195 38' Single 3450 3RMW15M2-21 3" Fl. Horiz. 1.5 230 1 195 38' Single 3450 3RMW15M2-03 3" Fl. Horiz. 1.5 200 3 195 38' Single 3450 3RMW15M2-23 3" Fl. Horiz. 1.5 230 3 195 38' Single 3450 3RMW15M2 3" Fl. Horiz. 1.5 200 1 195 38' Single 3450 3RMW20M2-03 3" Fl. Horiz. 2 230 3 215 45' Single 3450 3RMW15M4-01 3" Fl. Horiz. 1.5 200 1 218 25' Single 1750 3RMW20M2-21 3" Fl. Horiz. 2 230 3 215 45' Single 3450 3RMW20M2-23 3" Fl. Horiz. 2 200 1 215 45' Single 3450 3RMW20M2-43 3" Fl. Horiz. 2 460 3 215 45' Single 3450 3RMW20M2-01 3" Fl. Horiz. 2 200 1 215 45' Single 3450 3RMW15M4-21 3" Fl. Horiz. 1.5 230 1 218 25' Single 1750 3RMW15M4-23 3" Fl. Horiz. 1.5 230 3 218 25' Single 1750 3RMW15M4-43 3" Fl. Horiz. 1.5 460 3 218 25' Single 1750 3RMW15M4-03 3" Fl. Horiz. 1.5 200 3 218 25' Single 1750 3RMW20M4-43 3" Fl. Horiz. 2 460 3 245 31' Single 1750 3RMW20M4-23 3" Fl. Horiz. 2 230 3 245 31' Single 1750 3RMW30M2-21 3" Fl. Horiz. 3 230 1 235 50' Single 3450 3RMW20M4-21 3" Fl. Horiz. 2 230 1 245 31' Single 1750 3RMW20M4-01 3" Fl. Horiz. 2 200 1 245 31' Single 1750 3RMW30M2-03 3" Fl. Horiz. 3 200 3 235 50' Single 3450 3RMW30M2-23 3" Fl. Horiz. 3 230 3 235 50' Single 3450 3RMW20M4-03 3" Fl. Horiz. 2 200 3 245 31' Single 1750 3RMW30M4-03 3" Fl. Horiz. 3 200 3 275 35' Single 1750 3RMW30M4-21 3" Fl. Horiz. 3 230 1 275 35' Single 1750 3RMW30M4-43 3" Fl. Horiz. 3 460 3 275 35' Single 1750 3RMW30M4-23 3" Fl. Horiz. 3 230 3 275 35' Single 1750 3RMW15DM2-21 3" Fl. Horiz. 1.5 230 1 195 38' Dual 3450 3RMW15DM2-03 3" Fl. Horiz. 1.5 200 3 195 38' Dual 3450 3RMW15DM2-23 3" Fl. Horiz. 1.5 230 3 195 38' Dual 3450 3RMW20DM2-23 3" Fl. Horiz. 1.5 460 3 195 38' Dual 3450 3RMW20DM2-03 3" Fl. Horiz. 2 200 3 215 45' Dual 3450 3RMW20DM2-21 3" Fl. Horiz. 2 230 1 215 45' Dual 3450 3RMW20DM2-01 3" Fl. Horiz. 2 200 1 215 45' Dual 3450 3RMW20DM2-43 3" Fl. Horiz. 2 460 3 215 45' Dual 3450 3RMW15DM4-21 3" Fl. Horiz. 1.5 230 1 218 25' Dual 1750 3RMW15DM4-01 3" Fl. Horiz. 1.5 200 1 218 25' Dual 1750 3RMW15DM4-43 3" Fl. Horiz. 1.5 460 3 218 25' Dual 1750 3RMW15DM4-23 3" Fl. Horiz. 1.5 230 3 218 25' Dual 1750 3RMW15DM4-03 3" Fl. Horiz. 1.5 200 3 218 25' Dual 1750 3RMW20DM4-01 3" Fl. Horiz. 2 200 1 245 31' Dual 1750 3RMW20DM4-43 3" Fl. Horiz. 2 460 3 245 31' Dual 1750 3RMW30DM2-03 3" Fl. Horiz. 3 200 3 235 50' Dual 1750 3RMW20DM4-23 3" Fl. Horiz. 2 230 3 245 31' Dual 3450 3RMW30DM2-21 3" Fl. Horiz. 3 230 1 235 50' Dual 3450 3RMW20DM4-03 3" Fl. Horiz. 2 200 3 245 31' Dual 1750 3RMW30DM2-43 3" Fl. Horiz. 3 460 3 235 50' Dual 3450 3RMW20DM4-21 3" Fl. Horiz. 2 230 1 245 31' Dual 1750 3RMW30DM2-23 3" Fl. Horiz. 3 230 3 235 50' Dual 3450 3RMW30DM4-43 3" Fl. Horiz. 3 460 3 275 35' Dual 1750 3RMW30DM4-23 3" Fl. Horiz. 3 230 3 275 35' Dual 1750 3RMW30DM4-03 3" Fl. Horiz. 3 200 3 275 35' Dual 1750 3RMW30DM4-21 3" Fl. Horiz. 3 230 1 275 35' Dual 1750 PERFORMANCE CURVE BREAKDOWN DIAGRAM DIMENSIONS MANUAL Myers 3RMW Series Manual SPECIFICATIONS Myers 3RMW Series Specifications Sheet Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Myers 3RMW Series Sewage Pumps Buyers Guide & Review

January 19, 2018In this video, Pump Products highlights the Myeres 3RMW series sewage pumps. This pump series is well-suited to wastewater applications. Video includes all relevant features, specifications and benefits. View the product listings here: https://www.pumpproducts.com/myers-se... Pump Products' applications engineers are happy to work with customers to figure out the right pump for your application and budget. Call 1800-429-0800 to speak to an expert. Subscribe to our channel for more how-to guides, product highlights and general information about pumps.

-

Goulds 18GB/25GB/33GB Series Booster Pumps Buyers Guide & Review

January 17, 2018The Goulds 18GB/25GB/33GB Booster Pumps are portable, horizontally configured multistage pumps used for residential and agricultural washdown, misting, evaporative cooling, spray systems, general boosting service, and general pumping operations. The multistage design also allows for pumping to high heads while simultaneously operating quietly and vibration free. The Goulds GB series Booster Pumps are designed for durability and corrosion resistance. The elements of each stage are particularly tough: the impeller and diffuser are made of glass filled engineered composite material while the bowl is 300 stainless steel rabbit lock for positive alignment with no gaskets required. A high pressure o-ring sealing can easily be disassembled for easy maintenance or repair. The motor is designed for continuous operation. The primary difference between the two classes is the best efficiency GPM for each (18 GPM for the 18GB series, 25 GPM for the 25GB series, 33 GPM for the 33GB series). Goulds 18GB/25GB/33GB Series Booster Pump Model Comparison Chart Model Disch. HP Volt. Phase GPM Stages Type 18GBC07 1" NPT 3/4 115/230 1 18 5 Cast Iron 18GBC0712E0 1" NPT 3/4 230/460 3 18 5 Cast Iron 18GBC10 1" NPT 1 115/230 1 18 7 Cast Iron 18GBC0715E0 1" NPT 3/4 230/460 3 18 5 Cast Iron 18GBC0714E0 1" NPT 3/4 115/230 1 18 7 Cast Iron 18GBC1014G0 1" NPT 1 115/230 3 18 7 Cast Iron 18GBC1512J0 1" NPT 1.5 230/460 3 18 9 Cast Iron 18GBC15 1" NPT 1.5 115/230 1 18 9 Cast Iron 18GBC2012N0 1" NPT 2 230/460 3 18 13 Cast Iron 18GBC1514J0 1" NPT 1.5 115/230 1 18 9 Cast Iron 18GBC20 1" NPT 2 115/230 1 18 13 Cast Iron 18GBS0712E4 1" NPT 3/4 230/460 3 18 5 Cast Iron 18GBC2014N0 1" NPT 2 115/230 1 18 13 Cast Iron 18GBC1517J0 1" NPT 1.5 230/460 3 18 9 Cast Iron 18GBS10 1" NPT 1.5 115/230 1 18 7 Stainless Steel 18GBS1012G4 1" NPT 1 230/460 3 18 7 Stainless Steel 18GBS0715E4 1" NPT 3/4 230/460 3 18 5 Stainless Steel 18GBS0714E4 1" NPT 3/4 115/230 1 18 5 Stainless Steel 18GBS1014G4 1" NPT 1 115/230 1 18 7 Stainless Steel 18GBS1512J4 1" NPT 1.5 230/460 3 18 9 Stainless Steel 18GBC3012Q0 1" NPT 3 230/460 3 18 15 Stainless Steel 18GBS15 1" NPT 1.5 115/230 1 18 9 Stainless Steel 18GBS1514J4 1" NPT 1.5 115/230 1 18 9 Stainless Steel 18GBS2012N4 1" NPT 2 230/460 3 18 13 Stainless Steel 18GBS20 1" NPT 2 115/230 1 18 13 Stainless Steel 18GBC30 1" NPT 3 230 1 18 15 Stainless Steel 18GBS2014N4 1" NPT 2 115/230 1 18 13 Stainless Steel 18GBS1517J4 1" NPT 1.5 230/460 3 18 9 Stainless Steel 18GBC3014Q0 1" NPT 3 230 1 18 15 Stainless Steel 18GBS3012Q4 1" NPT 3 230/460 3 18 15 Stainless Steel 18GBS2017N4 1" NPT 2 230/460 3 18 13 Stainless Steel 18GBS30 1" NPT 3 230 1 18 15 Stainless Steel 18GBC3017Q0 1" NPT 3 230/460 3 18 15 Stainless Steel 18GBS3014Q4 1" NPT 3 230 1 18 15 Stainless Steel 18GBS3017Q4 1" NPT 3 230/460 1 18 15 Stainless Steel 25GBC07 1" NPT 3/4 115/230 1 25 5 Cast Iron 25GBC0712E0 1" NPT 3/4 230/460 3 25 5 Cast Iron 25GBC10 1" NPT 1 115/230 1 25 7 Cast Iron 25GBC0714E0 1" NPT 3/4 115/230 1 25 7 Cast Iron 25GBC1012G0 1" NPT 1 230/460 3 25 7 Cast Iron 25GBC0715E0 1" NPT 3/4 230/460 3 25 5 Cast Iron 25GBC1015G0 1" NPT 1 230/460 3 25 7 Cast Iron 25GBC1014G0 1" NPT 1 115/230 1 25 7 Cast Iron 25GBC1512J0 1" NPT 1.5 230/460 3 25 9 Cast Iron 25GBC15 1" NPT 1.5 115/230 1 25 9 Cast Iron 25GBC2012K0 1" NPT 2 230/460 3 25 10 Cast Iron 25GBC1514J0 1" NPT 1.5 115/230 1 25 9 Cast Iron 25GBS07 1" NPT 3/4 115/230 1 25 5 Stainless Steel 25GBC2014K0 1" NPT 2 115/230 1 25 10 Cast Iron 25GBS0712E4 1" NPT 3/4 230/460 3 25 5 Stainless Steel 25GBS10 1" NPT 1 115/230 1 25 7 Stainless Steel 25GBS0714E4 1" NPT 3/4 115/230 1 25 5 Stainless Steel 25GBS1012G4 1" NPT 1 230/460 3 25 7 Stainless Steel 25GBC1517J0 1" NPT 1.5 230/460 3 25 9 Cast Iron 25GBS0715E4 1" NPT 3/4 230/460 3 25 5 Stainless Steel 25GBS1014G4 1" NPT 1 115/230 1 25 7 Stainless Steel 25GBS1512J4 1" NPT 1.5 230/460 3 25 9 Stainless Steel 25GBC3012P0 1" NPT 3 230/460 3 25 14 Cast Iron 25GBS15 1" NPT 1.5 115/230 1 25 9 Stainless Steel 25GBC2017K0 1" NPT 2 230/460 3 25 10 Cast Iron 25GBS2012K4 1" NPT 2 230/460 3 25 10 Stainless Steel 25GBS1514J4 1" NPT 1.5 115/230 1 25 9 Stainless Steel 25GBS1017G4 1" NPT 1 230/460 3 25 7 Stainless Steel 25GBS20 1" NPT 2 115/230 1 25 10 Stainless Steel 25GBC30 1" NPT 3 230 1 25 14 Cast Iron 25GBS2014K4 1" NPT 2 115/230 1 25 10 Stainless Steel 25GBS1517J4 1" NPT 1.5 230/460 3 25 9 Stainless Steel 25GBC3014P0 1" NPT 3 230 1 25 14 Cast Iron 25GBS3012P4 1" NPT 3 230/460 3 25 14 Stainless Steel 25GBS2017K4 1" NPT 2 230/460 3 25 10 Stainless Steel 25GBS30 1" NPT 3 230 1 25 14 Stainless Steel 25GBC3017P0 1" NPT 3 230/460 3 25 14 Cast Iron 25GBS3014P4 1" NPT 3 230 1 25 14 Stainless Steel 25GBS3017P4 1" NPT 3 230/460 3 25 14 Stainless Steel 33GBC1012E0 1" NPT 1 230/460 3 33 5 Cast Iron 33GBC1512G0 1" NPT 1.5 230/460 3 33 7 Cast Iron 33GBC10 1" NPT 1 115/230 1 33 5 Cast Iron 33GBC1014E0 1" NPT 1 115/230 1 33 5 Cast Iron 33GBC15 1" NPT 1.5 115/230 1 33 7 Cast Iron 33GBC1514G0 1" NPT 1.5 115/230 1 33 7 Cast Iron 33GBC2012J0 1" NPT 2 230/460 3 33 9 Cast Iron 33GBC1017E0 1" NPT 1 230/460 3 33 5 Cast Iron 33GBC20 1" NPT 2 115/230 1 33 9 Cast Iron 33GBS1012E4 1" NPT 1 230/460 3 33 5 Stainless Steel 33GBC1517G0 1" NPT 1.5 230/460 3 33 7 Cast Iron 33GBC2014J0 1" NPT 2 115/230 1 33 9 Cast Iron 33GBS10 1" NPT 1 115/230 1 33 5 Stainless Steel 33GBS1014G4 1" NPT 1 115/230 1 33 5 Stainless Steel 33GBS1512G4 1" NPT 1.5 230/460 3 33 7 Stainless Steel 33GBC3012N0 1" NPT 3 230/460 3 33 13 Cast Iron 33GBS15 1" NPT 1.5 115/230 1 33 7 Stainless Steel 33GBC2017J0 1" NPT 2 230/460 3 33 9 Cast Iron 33GBS1514G4 1" NPT 1.5 115/230 1 33 7 Stainless Steel 33GBS1517G4 1" NPT 1.5 230/460 3 33 7 Stainless Steel 33GBS1017E4 1" NPT 1 230/460 3 33 5 Stainless Steel 33GBS2012J4 1" NPT 2 230/460 3 33 9 Stainless Steel 33GBC30 1" NPT 3 230 1 33 13 Stainless Steel 33GBS20 1" NPT 2 115/230 1 33 9 Stainless Steel 33GBS2014J4 1" NPT 2 115/230 1 33 9 Stainless Steel 33GBC3014N0 1" NPT 3 230 1 33 13 Cast Iron 33GBS3012N4 1" NPT 3 230/460 3 33 13 Stainless Steel 33GBC3017N0 1" NPT 3 230/460 3 33 13 Cast Iron 33GBS2017J4 1" NPT 2 230/460 3 33 9 Stainless Steel 33GBS30 1" NPT 3 230 1 33 13 Stainless Steel 33GBS3014N4 1" NPT 3 230 1 33 13 Stainless Steel 33GBS3017N4 1" NPT 3 230/460 3 33 13 Stainless Steel 33GBC5017U0 1" NPT 5 230/460 3 33 19 Cast Iron 33GBS5017U4 1" NPT 5 230/460 3 33 19 Stainless Steel 18GBC1012G0 1" NPT 1 230/460 3 18 7 Cast Iron 18GBC1017G0 1" NPT 1 230/460 3 18 7 Cast Iron 18GBC2017N0 1" NPT 2 230/460 3 18 13 Cast Iron 18GBS07 1" NPT 3/4 115/230 1 18 5 Stainless Steel 18GBS1017G4 1" NPT 1 230/460 3 18 7 Stainless Steel 25GBC1017G0 1" NPT 1 230/460 3 25 7 Cast Iron 25GBC20 1" NPT 2 115/230 1 25 10 Cast Iron PERFORMANCE CURVES BREAKDOWN BROCHURES Goulds GB Series Brochure MANUAL Goulds GB Series Instruction Manual SPECIFICATIONS No Specifications Sheet Available REPAIR PARTS Goulds GB Series Repair Parts List Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

PumpProducts.com: A One Stop Pump Supply House

January 17, 2018PumpProducts.com is a unique pump supply house that offers first-rate storefront service backed by a robust warehouse stocked with pumps, repair parts and controls from top manufacturers such as Goulds, Zoeller, Liberty, Berkeley and Myers. Does your customer need a new Goulds sump pump Chances are we have the actual pump in stock, ready for immediate pick-up. Our specialist Nick takes you on a tour of our Westwood, NJ facility.

-

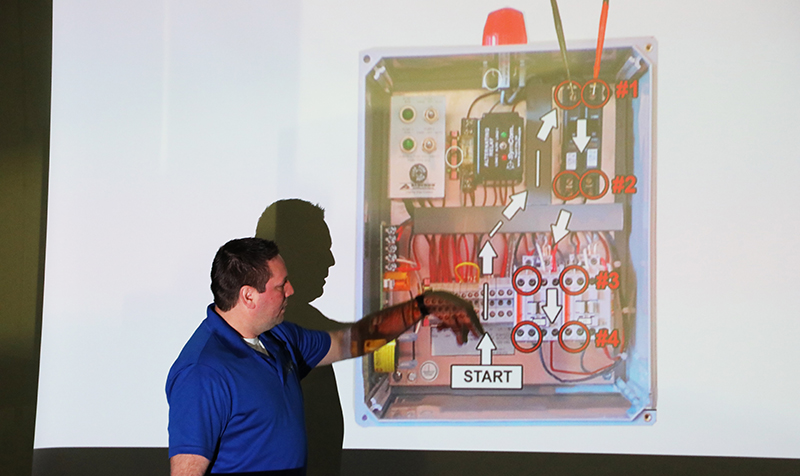

Inspector Pumphead’s Classroom: Training with Alderon Industries

January 11, 2018Pump Products staff members recently attended a technical training session with the national sales director of Alderon Industries, one of the company's newest manufacturing partners. Alderon specializes in making high quality control panels, floats and alarms.This session was part of a continuing effort by the team to better educate themselves on the products we carry and in turn help customers choose the best products for each one's need and budget. Ben Moy of Alderon conducted the illuminating training session using a PowerPoint presentation and several display control panels as physical examples. He started by laying out the history of Alderon Industries. Initially founded by one of the lead engineers of SJE Rhombus (then SJE Electric) control panels, Alderon's purpose was to create a new generation of control panels. One of the original Alderon designs introduced a rubber gasket in the lining of the panel door to keep out rain. The inspiration for the company's name indeed comes from the planet from "Star Wars"; the two cofounders were watching the classic sci-fi film while brainstorming potential names (though as any geek can tell you, the planet is spelled Alderaan in the movie). Moy walked the Pump Products crew through the basics of the popular "Check It" series of control panels. Perhaps the defining feature of this panel series is the ease of connecting the pump and floats to the right terminals due to careful labeling. Moy noted that with other panels, confusion can often reign. "In a lot of states, the only person who can set up a panel is a certified electrician. So a municipality will order the panel and have it sit for days, weeks even," he said. "By the time the electrician comes, they've thrown away the instructions and no one knows what goes where." All Check-It panels carry labels on the cords for the pump itself, the "off" float, the lead float and the alarm float (if applicable) to connect to the correct terminals. Moy also demonstrated how the circuit board is hardwired into the terminal and into the HOA (Hands Off Automatic) switch. Additional features in the panel include a pump run indicator, float switch indicators and alarm power indicators. Moy also demonstrated how a jump wire within the panel gives an alarm notification for manual reset. The jump wire can also be removed for automatic reset. The Pump Products team was also given a sneak preview of some exciting new Alderon products that could be due for release in March. Be sure to check back in this space for more information on them. "This was a really great technical training session in the sense that we were given a good demonstration of how the products look and how they operate," according to Pump Products application engineer Lee. "Seeing the detail in how the panel works will definitely help us in giving advice to customers." Pump Products is continuing to add more sessions to better understand manufacturer products. Be sure to take a look at the Alderon controls that we carry and call if you have any questions. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.