-

Pump Products Now Distributing New Grundfos Centrifugal Pumps

February 6, 2018Pump Products is proud to announce distributorship of several new multistage centrifugal pump lines from Grundfos Pumps: the CM series, the CME Plus series and the CR series. Grundfos is one of our most trusted manufacturing partners and Pump Products has had a long and successful relationship with the company. Grundfos pumps are famous in the industry for technical sophistication, reliability and consistent high performance. The CM series pumps were created with compactness, flexibility and performance reliability in mind and are typically used in washing, cleaning, temperature control, water treatment and irrigation applications. Each pump is of a horizontal, multistage close-coupled design and runs quietly. One of the special features is the Grundfos proprietary mechanical shaft seal technology which eliminated the common problem wherein the seal faces stick together. In addition, these pumps are low maintenance, service friendly and have a wide performance range within the series. The CME Plus series is, as the name suggests, an upgrade of the standard Grundfos CME pump. The CME Plus comes pre-wired and is used to provide constant water pressure in domestic applications. No more worrying about your water pressure fluctuating! The easy interface also allows the user to personalize the water pressure simply by pressing a button, while the stop function saves water if water usage drops past a certain point. CR series pumps are also multistage pumps that include a pump, motor and integrated Vertical Frequency Drive (VFD). These pumps are perfect for industrial processing systems, washing and cleaning, pumping acids, filtration systems, pressure boosting, water treatment, HVAC and irrigation. Compact with specially engineered functionalities, complete CR units (pump, motor, VFD) are tested together in the factory before shipping. "Grundfos engineering really pushes the envelope, it's amazing to see the new stuff they add to pumps," according Pump Products specialist Christian. "I think our customers are going to be really excited for these pumps." Pump Products sales specialists are standing by to help you find the right pump or part, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Quick Tips: Do Not Dry Run a Centrifugal Pump

January 26, 2018Here’s another minty-fresh edition of everyone’s favorite semi-recurring content feature: Inspector Pumphead’s Quick Tips! In this space, I, Inspector Pumphead from Pump Products, will be sending out friendly reminders and dispensing basic tips for ordering, maintaining and servicing pumps. The Inspector is in and here to help! Quick Tip: Dry running a centrifugal pump can cause damage to your pump and system. A centrifugal pump uses the kinetic energy generated by the rotation of the impeller to transport water. Keep in mind that most of the pumps we sell are centrifugal pumps. The liquid that the pump transports is key to counteracting the heat generated by the impeller's motion and keeping both the pump body and motor cool. When and if the pump is run dry, there is no water to counter and slow the motion of the impeller. Speed increases past the desired point and the heat generated increases as well. This could cause sparking, overheating, melted plastic and a busted pump that needs immediate replacement. We've heard plenty of horror stories of warped pumps that were run dry for one reason or another. So make sure to periodically check your pump and make sure that the water is flowing smoothly and consistently to your pump. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

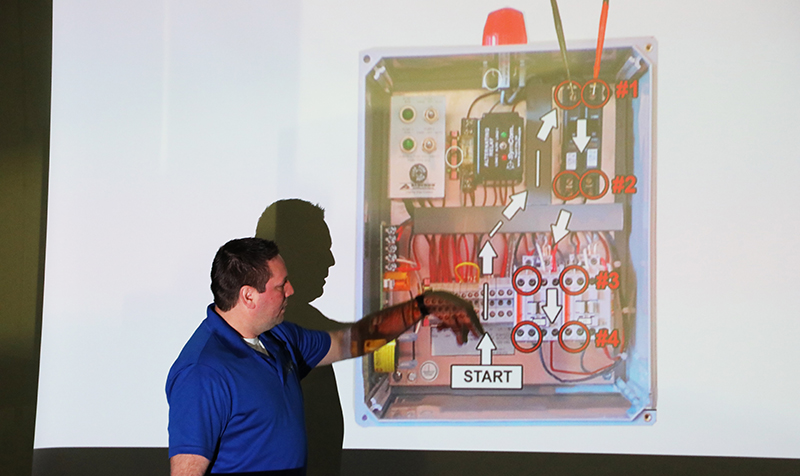

Inspector Pumphead’s Classroom: Training with Alderon Industries

January 11, 2018Pump Products staff members recently attended a technical training session with the national sales director of Alderon Industries, one of the company's newest manufacturing partners. Alderon specializes in making high quality control panels, floats and alarms.This session was part of a continuing effort by the team to better educate themselves on the products we carry and in turn help customers choose the best products for each one's need and budget. Ben Moy of Alderon conducted the illuminating training session using a PowerPoint presentation and several display control panels as physical examples. He started by laying out the history of Alderon Industries. Initially founded by one of the lead engineers of SJE Rhombus (then SJE Electric) control panels, Alderon's purpose was to create a new generation of control panels. One of the original Alderon designs introduced a rubber gasket in the lining of the panel door to keep out rain. The inspiration for the company's name indeed comes from the planet from "Star Wars"; the two cofounders were watching the classic sci-fi film while brainstorming potential names (though as any geek can tell you, the planet is spelled Alderaan in the movie). Moy walked the Pump Products crew through the basics of the popular "Check It" series of control panels. Perhaps the defining feature of this panel series is the ease of connecting the pump and floats to the right terminals due to careful labeling. Moy noted that with other panels, confusion can often reign. "In a lot of states, the only person who can set up a panel is a certified electrician. So a municipality will order the panel and have it sit for days, weeks even," he said. "By the time the electrician comes, they've thrown away the instructions and no one knows what goes where." All Check-It panels carry labels on the cords for the pump itself, the "off" float, the lead float and the alarm float (if applicable) to connect to the correct terminals. Moy also demonstrated how the circuit board is hardwired into the terminal and into the HOA (Hands Off Automatic) switch. Additional features in the panel include a pump run indicator, float switch indicators and alarm power indicators. Moy also demonstrated how a jump wire within the panel gives an alarm notification for manual reset. The jump wire can also be removed for automatic reset. The Pump Products team was also given a sneak preview of some exciting new Alderon products that could be due for release in March. Be sure to check back in this space for more information on them. "This was a really great technical training session in the sense that we were given a good demonstration of how the products look and how they operate," according to Pump Products application engineer Lee. "Seeing the detail in how the panel works will definitely help us in giving advice to customers." Pump Products is continuing to add more sessions to better understand manufacturer products. Be sure to take a look at the Alderon controls that we carry and call if you have any questions. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Video Classroom: How To Read a Pump Curve Chart

December 18, 2017Welcome back to another exciting edition of Inspector Pumphead's Video Classroom! In this feature, I, Inspector Pumphead, will tackle a common question about pumps, parts or water systems using fun visual aids. This video is designed for those who like visual learning or enjoy a bit of fun in the classroom! In today's feature, my assistant Mike, will explain how to read a pump curve chart. The pump curve is something you should be able to find in the corresponding literature for any pump we sell. It is simply a visual representation of the pump's performance. The graph may be confusing or intimidating to those who don't consider themselves technically savvy, but fear not! This isn't a replay of calculus; curves are actually pretty simple to read. The above video will discuss the most basic type of curve which identifies pump performance through two variables: flow rate (or capacity) and total dynamic head. Those are the two basic things you need to know to identify what pump goes with your system. In the above example, Mike uses a curve from a Goulds WW05 3872 sewage pump. For those of you that like a written guide to go with your videos, read on below for a repost of a previous blog about pump curves. It goes into a little more detail and talks about more advanced curves as well. A Pumphead Classic all right! A common question that customers ask Pump Products application engineers is, "What am I looking at" in reference to the pump curve charts you can often find in technical manuals and brochures. The pump curve is simply a visual representation of the conditions in which the pump ca n operate. At the most basic level the relationship between flow (plotted on the x-axis) and head (y-axis) is displayed. Thus, if you know the total dynamic head capability of the pump, you can easily determine how many gallons per minute the pump can move. Knowing how to read a pump curve chart can help you pick the most efficient pump for your application, keep that pump running in optimal condition, and ensure a long operating life. If you need to replace a pump, the information can also help estimate flow rates for an existing system. Put simply, understanding the information on a pump curve chart can save you time, money, and a lot of maintenance effort in the long run. In this blog post, we will walk you through reading a basic flow-head curve and give a primer on reading more intermediate and advanced curves as well. (more…)

-

Inspector Pumphead’s Classroom: Training with See Water, Inc.

November 20, 2017As part of an ongoing effort to provide the best possible service for all product lines, Pump Products employees attended a training session with a representative from See Water Inc. See Water, located in Riverside, CA, is one of Pump Products' newest manufacturing partners and is renowned in the industry for its line of innovative water products and controls. Pump Products currently carries a plethora of quality wastewater pump control accessories from See Water, including water level alarms, control panels and junction boxes. Eric Wallace, Vice President of Operations at See Water, gave a presentation lecture in which he dove into the history of the company, its products, and practices for ensuring across the board customer satisfaction. "We're a customer-driven company and we pride ourselves on great customer service," he said. "Our focus is always on the end user." Wallace said that this focus is best exemplified by the simplicity and straightforwardness of See Water installations. He described his ideal customer interaction as, one in which the customer is able to install the product so easily that he feels compelled to call the company to make sure the process really is that simple. That's why many See Water products are "plug and play" an approach that emphasizes the end user in the consumer interaction chain. This produces return customers, and according to Wallace, there's nothing See Water likes more than return customers. It is a philosophy that Pump Products shares as well. Another, incredible fact is that, all See Water products are constructed at the company facility in Riverside, CA. Having everything manufactured in the U.S., is an important mark of quality. All products are also UL-listed and CSA certified for the U.S. and Canada. Such customer care also extends to the warranty process. Most See Water products (except custom builds) include a 3-year warranty. Wallace estimates that "90%" of warranty issues are able to be resolved through calling the company directly and troubleshooting. This allows the user or contractor to solve the problem onsite. In cases where that doesn't work out, customers can send the product back to See Water for thorough examination. "We're just interested in the customer being happy," he said. Testing is also an important aspect of the process. Each product that leaves the warehouse is factory tested before it is packaged. Wallace emphasized that the testing is not a la carte but holistic. "We don't have a station with a bunch of floats and then hook up a panel to test it," he said. "We test each control panel with the specific float that will be in the package before it gets sent out. That way the customer is sure to get everything that works." For lead times, prebuilt products can usually be sent to Pump Products within a matter of days. Custom panels can take up to four weeks but See Water tries to push those panels through sooner if possible, particularly for repeat customers. See Water also emphasizes the commonality of various parts and components across various types of panels. This allows the engineers to rig up all sorts of custom panels, with special custom features, tailored to make the user's life much easier. Some of these features include but are not limited to: touchscreen interfaces, variable frequency drives, programmable logic controllers, multiple alarms (that can be run back to a main alarm) and solar alarms. The thoroughness of the engineering process allows for a lot of same-day and next day quotes on custom panels. Making sure exactly what each customer needs, also reduces the risk of returns and call-backs. "It was a really interesting and informative lecture," Pump Products application engineer Nick said. "It's always good to get insight into how other companies interact with customers and think about how we can apply those practices here [at Pump Products]." The training session with See Water is part of a continual effort by the Pump Products staff to familiarize themselves with manufacturer products, to deliver the best possible service and product information to our customers. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Classroom: How to Replace a Pump Bearing Assembly

November 10, 2017Welcome to another exciting edition of Inspector Pumphead's Classroom! In this feature, we'll be talking about various small, simple pump "How-To's" that any homeowner, small business owner or facilities manager can tackle. The purpose of this feature is to help customers become more familiar with the parts of a pump and give them the confidence to make the necessary fixes to keep the system running smoothly. In this edition, Pump Products application engineer Nick, will walk you through the process of replacing a bearing assembly on a three-piece circulator pump from Bell & Gossett. The bearing assembly is the unit between the motor and the volute/pump casing. It contains the connecting shaft that powers the impeller, allowing the pump to move fluid. A good indicator that the bearing assembly needs a replacement, is if you hear strange noises coming from that area on the pump. If a seal or coupler snaps, you might hear a squeaking or shaking noise. You might also see traces of oil or water leakage in the pump area. Since the bearing is what keeps both ends of the pump functioning together, it is important to replace one right away if defective. Pump Products expert Nick walks you through the replacement process in the video below: The pump used for the breakdown is the Bell & Gossett 102210 HV NFI, a top flight circulator. The bearing assembly replacement package is the B&G 189166LF , which includes the attached impeller, a replacement gasket and lubricant. Note: While B&G repair parts are used in the example for this video, Pump Products also carries Taco pump repair parts, Grundfos pump repair parts, Armstrong pump repair parts and Wilo pump repair parts, among others. Tools and supplies --1 ⅝” combination wrench --1 7/16" combination wrench --1 Allen wrench/hex key --Lubricant (should come in the replacement package) --Replacement bearing assembly --Alcohol wipes Process As always when working on a pump, be sure to turn off the motor and shut down the water flow moving through the pump. For this process you will not have to remove the pump end from the piping. Identify the bearing assembly of the pump. It should be between the wet end and the motor of the pump. First you will detach the motor end from the bearing assembly. For this attachment you will use the box end of the 7/16" wrench. Use the wrench to carefully loosen the bolts. Pull the bearing assembly away from the motor, and inside you will find a spring-style coupler which connects the two units. This is where you will use your Allen key. On each end of the coupler will be an indentation where it connects to the shaft. Use your Allen key to loosen the connections and remove the coupler. Take out the coupler and put it and the motor down somewhere safe. Unless you bought a replacement, you will need to reattach the existing coupler. Next, turn your attention to the other end of the bearing assembly, which is also connected by four bolts to the volute. For this part you will use the box end of your ⅝” combination wrench to loosen and remove the bolts. You can now remove the old bearing assembly. Inside the lip of the volute should be a rubber gasket. Remove the gasket and examine the lip area for any impurities or imperfections. This area is important for creating a watertight seal, so be sure to wipe it down with alcohol wipes or a similar cleaning agent until the area is clean. Now you can install your replacement bearing assembly. This will simply be the deconstruction process in reverse. Insert the end with the impeller into the volute, reapply the bolts and tighten in a criss cross pattern to ensure a watertight seal. Next, you will to have reattach the spring coupler. Remove the the piece of cardboard from the impeller shaft in the bearing assembly and find the right indentation groove. Match up the groove on the coupler and shaft, insert the hex key until it is flush to the area and tighten. You will need to repeat the coupler process with the shaft end of the motor unit. Once the coupler is secure, you can reattach the motor end completely and tighten the bolts. Since there is no watertight seal between the motor and bearing assembly, you do not necessarily have to use the criss cross pattern. Since the pump used in this example is not maintenance free, you will have to apply some lubrication (a bottle should be included with your package). Find the insert cap above the bearing assembly, fill with oil until the bottle is empty or oil starts to accrue at the top of the cap. Close the cap and you are ready to turn the pump and water flow back on. So that's it! It's a relatively simple process. As always, be sure to examine your pump regularly and practice preventative maintenance. If you have any ideas for other 'How-To' guides you'd like to see, let us know in the comments. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Pump Products Now Carrying Grundfos SQ Series Submersible Well Pumps

November 7, 2017Pump Products is proud to announce that the company is now distributing a new product line from Grundfos Pumps, the Grundfos SQ series submersible well pumps. The introduction of the SQ series marks the expansion of a longstanding and fruitful partnership. Pump Products currently carries many other products and lines from Grundfos. The SQ series is an innovative, premium pump series specifically designed to simplify the installation process and improve the overall reliability of your well pump system. Each SQ pump includes several special features precision engineered by the Grundfos team to increase performance. These 3" submersible pumps can operate both continuously and intermittently for domestic water supply, light commercial water supply, irrigation and tank applications in 3" or larger diameter wells, SQ pumps come close coupled to an innovative motor design that uses permanent magnet technology and a Grundfos motor to electronically control the motor speed. This allows for several features such as constant pressure, control, soft-start and integrated dry-run protection. The smart motor communicated via a status box through the power leads so it is not required to run additional wires down the well. The motor design also protects against overvoltage, undervoltage and voltage fluctuation, ensuring a longer performance life. The motor is also uses a low amperage making it possible to connect more appliances to the same fuse group. The pump design features floating impellers that are not fashioned to the shaft for increased wear resistance and protection against upthrust. Overload protection and temperature protection are also included. All in all, Grundfos SQ series well pumps are an advanced high quality option for the discerning consumer. The quality performance, engineering and long life are sure to make this a popular well pump. "I don't think a lot of U.S. distributors carry this line, so we're really excited to have the opportunity," application engineer Nick said. "Grundfos makes a quality product so I'm sure our customers will be happy." Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Classroom: How To Change a Circulator Pump Cartridge

November 2, 2017Welcome to another exciting edition of Inspector Pumphead's Classroom! In this feature, we'll be talking about various small, simple pump "How-To's" that any homeowner or facilities manager can tackle. Next up: How to Replace the Cartridge on a Taco 007 Circulator Pump. As the name suggests, circulator pumps are used to keep hot water circulating throughout your water system so that it is immediately available at point of use. For those of us who live in colder climates, the coming winter months are a particularly annoying time to have to wait for water at the sink or tub to heat up. The presence of a circulator pump ensures that hot water is always readily available. The Taco 007 is built for quiet operation in hydronic heating, radiant heating, hydro-air fan coils, indirect water heaters, chilled fresh water and domestic water circulating systems. The cartridge style design means the actual circulating mechanism is contained in an easily serviceable or replaceable single unit. It is perhaps the most popular cirulator on the market and plenty are always available in stock. In the video below, Pump Products application engineer Nick, who I have personally trained, will walk you through the process of replacing the cartridge, using the Taco 007-F5 pump and the proper Taco replacement cartridge (the cartridge package should also include a replacement gasket and spare bolts as well). You can also purchase the full suit of Taco Repair parts. You can also continue reading below for a written breakdown. Items and Materials The only tool you'll need is a hexagonal Allen key (or Allen wrench). Make sure you have the replacement cartridge handy as well. Steps --Turn off the water flowing through your system. You do not need to remove the pump base outlets from the piping. --Identify the four casing bolts. --One by one, use the proper Allen key to loosen the bolts. --Remove the bolts. --Remove the motor casing from the volute. Inside the motor casing you will see the cartridge. --The cartridge should be solidly in place. Tug gently but firmly until the cartridge is out of the casing. --Discard used cartridge. --Take the replacement cartridge and firmly insert into the volute. --Firmly place the replacement rubber gasket into the lip of the volute base. The gasket is important for creating a seal. --Line up the base plate and the volute to the base and connect them. Be sure to match up the bolt holes. --Insert the bolts and tighten only until each is roughly equally snug. Uneven tightening could cause leaks in one area. --Complete the tightening on all four bolts in a crisscross pattern to ensure evenness on all sides. And there you have it. It's a simple and cheap process, one that any person should reasonably be able to complete. With winter upon us, making sure your circulator pump and cartridge are up to the task at hand is very important. Do you have any suggestions for other "How To" videos you'd like to see Let us know in the comments! Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Video Classroom: Manual Pumps vs. Automatic Pumps

September 28, 2017Welcome to Inspector Pumphead's video classroom! In this feature, I Inspector Pumphead will provide a video lecture on a subject related to pumps, parts and accessories. I hope you take good notes and pay close attention because we just might test you at the end! In this video lecture, my assistant Mike will talk about the difference between manual pumps and automatic pumps. My most attentive students will know that I've talked about this before! Watch the video or read below for further explanation. Manual vs. Automatic As the name suggests, manual cords operate when the power cords are plugged into an eletrical outlet. This grants the user control over the timing of an operation. This mode of operation is popular if you are on a job site or need to evacuate water temporarily (or if you're a control freak I guess). Manual pumps are often used in conjunction with a control panel as well. Automatic pumps use some kind of switch mechanism to activate the pump under certain conditions. The most popular kind is probably a tethered style float switch, which is attached by a cord to a pump and activates when the water level reaches a certain point. Watch the video for a cool animation example. Once you've watched the video, take the quiz below! If you complete the quiz, you'll get a coupon code for a $5 discount on any order of $30 or more! Offer valid until October 28, 2017. [WpProQuiz 3] Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.

-

Inspector Pumphead’s Classroom: Training with A.Y. McDonald

September 14, 2017Pump Products recently held a training seminar and Q&A session with Michael, the Northeast territory manager representing A.Y. McDonald Mfg. Co. This training session was just one of a number of such sessions designed to familiarize Pump Products application engineers and marketing staff with a manufacturer’s products, processes and customer service capabilities. Pump Products employees will in turn be able to better communicate about those products to customers. The talk centered specifically on A.Y. McDonald’s versatile and well-built submersible well pump line. The strength of A.Y. McDonald well pumps lies in their quality construction; all pump ends are made and manufactured in the United States. The target market for these well pumps is the discerning consumer who is willing to pay for quality manufacturing. While A.Y. McDonald has experimented with imported pump ends in the past, according to Michael, the company has rededicated itself to domestic manufacturing centered in its factory in Dubuque, IA. Keeping design and manufacture in-house allows the company to have “wonderful customer service,” according to Michael. “It’s a very tight knit and family-oriented group,” he said. The focus on customer service is particularly important for A.Y. McDonald because it is a “boutique” manufacturer. That focus extends to shipment (A.Y. McDonald can drop ship directly from the factory) and to the warranty process. Most pumps carry a one year warranty, but extended warranties up to three and five years are also available. Michael estimated that he fields about one warranty request per month. The group also talked about A.Y. McDonald’s vaunted SludgeMaster pump. Commonly used to get radon out of water cisterns, the SludgeMaster is powered by an air compressor and can evacuate mud, gunk, leaves, twigs and other waste from a system. While it can’t run on pure solids - the pumping medium should be about 70% liquid - the SludgeMaster is still a heavy duty pump. It has been described as an “animal” or “beast.” All in all, it was an enlightening and invigorating training session that strengthened the partnership between Pump Products and A.Y McDonald and has better equipped Pump Products to better serve the customer needs. Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800.

-

Pump Products is Now Carrying See Water Inc. Pump Controls

September 6, 2017Pump Products is proud to announce a new distributing partnership with See Water Inc., a premier distributor of controls, alarms, switches and other accessories for pumping systems. Located in Riverside, CA, See Water Inc. was founded in 1995 by Ron MacDonald when he realized there was a need in the market for a pump control that could work in oil containment areas and elevator sump pits. The Oil Smart pump control was the first step, and See Water, Inc. has since expanded to a variety of pumping accessory products for wastewater, HVAC and utility pumping systems (among others). Pump Products currently carries See Water liquid level alarms, control panels and float switches designed for use in conjunction with sewage and sump pumps. See Water alarms are designed for easy installations and comes equipped with external terminals for floats and alarm status indication. The HLA liquid alarm models are “plug and play” for simple and fast installation. These alarms are specifically used to detect dangerous water levels and most packages include a narrow angle float switch. Visible indicators include a green power-on indicator and a red LED alarm light. Audible indicators include an 85 decibel sound. Also included is an automatic reset when the liquid level reverts to normal levels. Alarms are rated for NEMA indoor/outdoor enclosures. Control panels are available in simplex and duplex configurations for use in conjunction with either single or three phase pumps. Triplex control panels are also available specifically for use with three phase pumps. See Water control panels are designed for quick installation and simple maintenance; in stand-by mode they are designed to use minimal power. Most control packages will include the control box, integrated electronic control, alarm and a float switch (some packages have up to three float switches). Individual float switches from See Water are also available for separate purchase. See Water float switches are normally open, with wide/narrow angle and piggyback options are available. All in all, See Water Inc. is a fine manufacturer of pump control systems and accessories and Pump Products is proud to distribute these products to customers in need. Pump Products application engineers are standing by to help you select the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800.

-

Inspector Pumphead’s Quick Tips: How To Create a PumpProducts.com Account

August 22, 2017Here’s another minty-fresh edition of everyone’s favorite semi-recurring content feature: Inspector Pumphead’s Quick Tips! In this space, I, Inspector Pumphead from Pump Products, will be sending out friendly reminders and dispensing basic tips for ordering, maintaining and servicing pumps. The Inspector is in and here to help! Today I talk about making a dedicated account for ordering new products. Tip: Create an account on PumpProducts.com for quick ordering, account and billing history and to receive special offers. Making an account with Pump Products is super easy. We explain the process in the video below, but you can also go directly to the login page and follow the listed instructions. Just go to the "My Account" menu at the top of the homepage and click the "Register Now" button in the drop-down or alternatively go straight to https://www.pumpproducts.com/login.html. Some of the many benefits of creating your own account include: --Faster checkout and order processing. --The ability to save your payment method for any future orders. --View order and billing history. --Rate products and write reviews. --Access to the Q & A section. That last aspect is relatively new and will allow you to ask questions about specific products before purchasing. Either I, Inspector Pumphead, or one of my disciples will answer your question promptly and directly. You can see some examples by clicking on the "Q & A" tab on the page for the Zoeller M53 Mighty Mate effluent pump, one of our most popular pumps. So with all of those great features and benefits, there's no reason not to make an account today! Pump Products application engineers are standing by to help you select the right pump, as well as to provide pricing, stocking availability and shipping information. Call our toll free number 1-800-429-0800.