Welcome to Inspector Pumphead’s classroom. This is the place where the Inspector likes to teach everything he knows about all the parts and components that makeup pumps! This is also the place where he likes to talk about himself in the third person. In this week’s edition the Inspector will be discussing what a pressure switch is and how they operate. The Inspector would also like to point out that if you ever inspect your pressure switch, always make sure the power to it is OFF for safety’s sake.

Pressure switches are commonly associated with well pumps. Well pumps deliver the clean water to your house that you use for drinking, watering the garden, and loading the unnecessarily-large-but-you-can-never-have-too-much-firepower Super Soaker that you terrorize your neighbors with. What, just me? But the Inspector digresses…

To put it in a nutshell, pressure switches basically tell the pump when to turn on and when to turn off. A more technical definition of a pressure switch sounds like this: a device that monitors pressure and provides an output when a set pressure is reached. The specific pressure that opens and closes the switch is called the set point. Many residential pressure switches are designed for a minimum of 30 PSI and a maximum of 50 PSI (or pounds per square inch). So in this example when the pressure in the system drops to 30 PSI, the switch activates and lets more water flow into the system. At 50 PSI, the switch turns off.

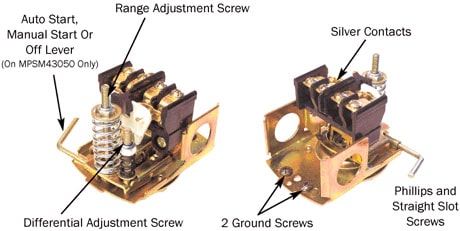

Pressure switches are comprised of several components including an adjustment screw, diaphragm, lever, and contacts. The adjustment screw sets the spring pressure. This can be adjusted to change the on-and-off pressure range that the switch operates at. The standard range of a pressure switch is usually located on the unit itself or on the box it comes in. You can always check online as well if you know the model number.

Pressure switches rely on water pressure to do all the work. The change in pressure that activates the switch is provided via the water from the well. The pressure moves up through the diaphragm which presses against a piston and spring, which in turn opens or closes the contacts. Open contacts located within the switch, closes when pressure drops. This completes an electrical circuit, which in turn activates the pump. When the set pressure is reached, this allows the contacts to open again which turns off the pump.

Pressure switches are usually wired to a control box. Wires from the box are connected to separate terminals within the switch while other terminals are connected to a power supply.

If you have any questions about pressure switches or if you’re in need of a replacement, you can give our pressure switch page a look or give a call to one of our PumpProducts.com application engineers. They’re waiting for your call and would be happy to help you figure out which pressure switch is right for your application. They have been personally trained by the Inspector so they know what they’re talking about! Check in next time to the Inspector’s classroom where he will be getting into pressure switch troubleshooting, adjusting, and maintenance tips!

Pump Products applications engineers are standing by to help you find the right pump, as well as to provide price quotes, availability and shipping information. Call our toll free number 1-800-429-0800.