This series of submersible pumps is designed for use in residential or commercial dewatering applications and can be used to transfer groundwater and wastewater. These durable cast iron pumps include a powder coated epoxy finish to prevent corrosion and are designed to meet specifications with assurance by using high temperature parts rated for continuous 200 °F (93 °C) contact. Available in a variety of models and performances, each pump is 100% factory tested to ensure quality and reliability for years of trouble-free performance! This attention to detail is an inherent feature of every model in this pump series, making it one of the most reliable in the industry.

Features

- A high temperature, submersible pump series with electrical components meeting the National Electrical Code requirements for 200 °F (93 °C) service

- Comprehensive line of models, styles, and modes

- Conduit length is 3′ (0.9 m) for automatic models and 6′ (1.8 m) for non-automatic models

- Power cord length is 15′ (5 m) for automatic models and supplied by others for non-automatic models

- High-temperature liquid-tight conduit used with high temperature cable

- High-temperature motor windings

- High-temperature Viton® gaskets

- High-temperature thermal overload protected

- All control components in contact with water are high temperature rated

- All models have stainless steel screws, guards, handles, and control arm and seal assemblies

- Float-operated mechanical switch box, which is mounted on the discharge pipe above the operating level (switch box is not intended to come in continuous contact with 200 °F [93 °C] water)

- Mechanical seal has NI-Resist rotary face and Viton® elastomer

- Corrosion-resistant, powder coated epoxy finish

Notes

- Cable from disconnect to control box (customer furnished) should be rated 105 °C (221 °F).

- Nonautomatic models available with 6 ft (1.8 m) of high temperature liquid-tight conduit cable (200 °F / 93 °C) and a watertight junction box for outdoor or above the waterline installation.

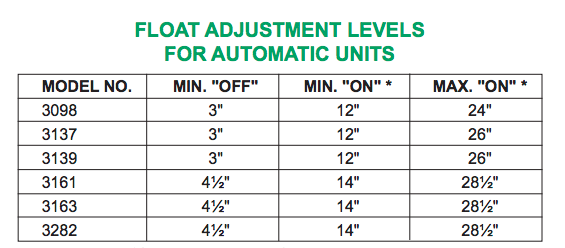

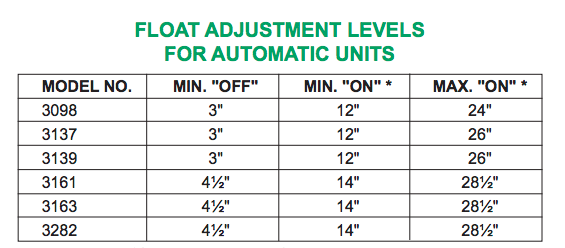

- The maximum ‘On’ levels can be extended for automatic pumps by adding additional cord and conduit length. Float rods are extended in 1 ft increments. Order an extender kit P/N 10-0656 for each additional foot of length desired.

| ZOELLER 3000 SERIES HIGH TEMPERATURE PUMPS |

Model Comparison Chart

| Model |

Discharge (NPT) |

HP |

Voltage |

Phase |

GPM |

Max. Head |

| M3137 |

1-1/2″ |

0.5 |

115 |

1 |

90 |

25′ |

| D3137 |

1-1/2″ |

0.5 |

230 |

1 |

90 |

25′ |

| E3282 |

2″ |

0.5 |

230 |

1 |

115 |

24′ |

| M3282 |

2″ |

0.5 |

115 |

1 |

115 |

24′ |

| D3282 |

2″ |

0.5 |

230 |

1 |

115 |

24′ |

| N3163 |

1-1/2″ |

0.5 |

115 |

1 |

53 |

60′ |

| N3161 |

1-1/2″ |

0.5 |

115 |

1 |

106 |

105′ |

| E3161 |

1-1/2″ |

0.5 |

230 |

1 |

106 |

105′ |

| E3163 |

1-1/2″ |

0.5 |

230 |

1 |

53 |

20′ |

| M3161 |

1-1/2″ |

0.5 |

115 |

1 |

106 |

105′ |

| M3163 |

1-1/2″ |

0.5 |

115 |

1 |

53 |

60′ |

| D3163 |

1-1/2″ |

0.5 |

230 |

1 |

53 |

60′ |

| D3161 |

1-1/2″ |

0.5 |

230 |

1 |

106 |

105′ |

| N3098 |

1-1/2″ |

0.5 |

115 |

1 |

65 |

24′ |

| E3098 |

1-1/2″ |

0.5 |

230 |

1 |

65 |

24′ |

| M3098 |

1-1/2″ |

0.5 |

115 |

1 |

65 |

24′ |

| D3098 |

1-1/2″ |

0.5 |

230 |

1 |

65 |

24′ |

| N3137 |

1-1/2″ |

0.5 |

115 |

1 |

90 |

25′ |

| D3137 |

1-1/2″ |

0.5 |

230 |

1 |

90 |

25′ |

| N3282 |

2″ |

0.5 |

115 |

1 |

115 |

24′ |

Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.