This series of residential or light commercial effluent or dewatering submersible pumps are used for groundwater, septic tank, low pressure pipe (LPP) and enhanced flow STEP systems. The durable 140 series includes a powder coated epoxy finish to prevent corrosion and is designed to provide great heat dissipation from the motor, ensuring a long service life. Each unit is 100% pressure-tested, submerged, and run to ensure quality and reliability for years of trouble-free performance.

- Durable, cast iron construction

- Model 140 features a non-clogging, engineered thermoplastic, vortex impeller design and passes 1/2″ (13 mm) spherical solids.

- Model 145 features an engineered thermoplastic, single vane impeller design and passes 3/4″ (19 mm) spherical solids.

- Oil-filled and hermetically-sealed, automatic reset thermal overload protection

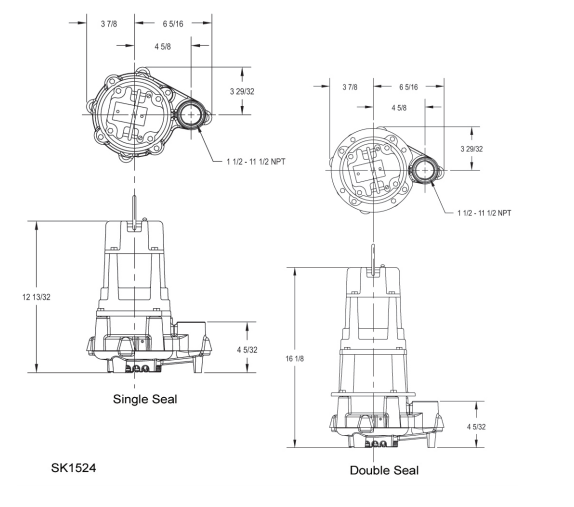

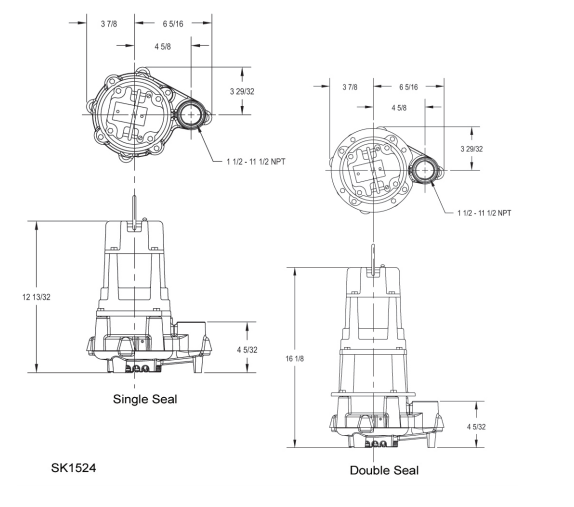

- Available in both single and double shaft seal designs

- Carbon/ceramic mechanical shaft seals

- Stainless steel bolts and lifting handle

- Upper sleeve and lower ball bearing running in bath of oil

- 1-1/2″ NPT vertical discharge

- Operates at 130 °F (54 °C) in effluent or dewatering applications

- BN and BE models include a variable level float switch and 1-1/2” x 2” PVC adapter fitting

- Corrosion-resistant, powder coated epoxy finish

Consult Factory for Special Applications

- Electrical alternators for duplex systems are available and supplied with an alarm

- Mechanical alternators for duplex systems are available with or without alarms

- Control alarm systems are available for 1 Ph pumps used in simplex systems, see FM0732

- Variable level control switches are available for controlling 1 Ph systems

- Double piggyback, variable level float switches are available for variable level long cycle controls

- Sealed Qwik-Box available for outdoor installations, see FM1420

- Consult factory for applications over 130 °F (54 °C)

| ZOELLER 140 SERIES EFFLUENT PUMPS |

Zoeller 140 Series Effluent Pump

Model Comparison Chart

| Model |

Discharge (NPT) |

HP |

Voltage |

Phase |

GPM |

Max. Head |

| E145 |

1-1/2″ |

3/4 |

230 |

1 |

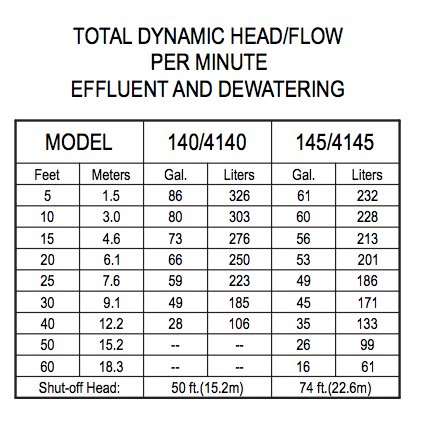

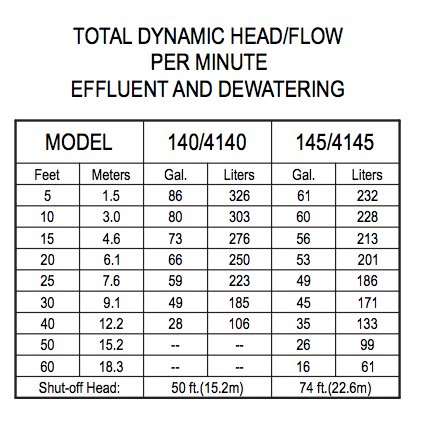

61 |

74′ |

| N140 |

1-1/2″ |

1 |

115 |

1 |

86 |

50′ |

| N145 |

1-1/2″ |

3/4 |

115 |

1 |

61 |

74′ |

| BN145 |

1-1/2″ |

0.7 |

115 |

1 |

61 |

74′ |

| E140 |

1-1/2″ |

1 |

230 |

1 |

86 |

50′ |

| BN145 |

1-1/2″ |

3/4 |

115 |

1 |

61 |

74′ |

| BE145 |

1-1/2″ |

3/4 |

230 |

1 |

61 |

74′ |

| BE140 |

1-1/2″ |

1 |

230 |

1 |

86 |

50′ |

| N4140 |

1-1/2″ |

1 |

115 |

1 |

86 |

50′ |

| N4145 |

1-1/2″ |

3/4 |

115 |

1 |

61 |

74′ |

| BN4140 |

1-1/2″ |

1 |

115 |

1 |

86 |

50′ |

| BN4145 |

1-1/2″ |

3/4 |

115 |

1 |

61 |

74′ |

| E4140 |

1-1/2″ |

1 |

230 |

1 |

86 |

50′ |

| E4145 |

1-1/2″ |

3/4 |

230 |

1 |

61 |

74′ |

| BE4140 |

1-1/2″ |

1 |

230 |

1 |

86 |

50′ |

Pump Products application engineers are standing by to help you find the right pump, as well as to provide price quotes, stocking availability and shipping information. Call our toll free number 1-800-429-0800 to speak to an expert today.